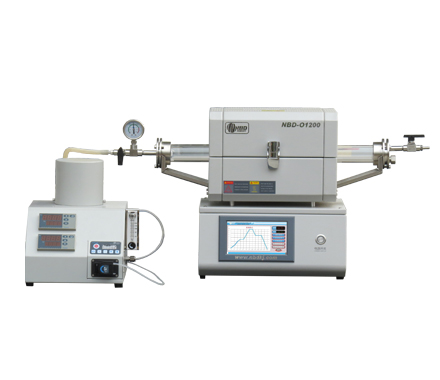

Vertical tube Furnace (LT1700-80TI)

Release time: 2021-03-29 13:13:50 Number of views: 3232

Equipment introduction:

Vertical tubular furnace adopts the structure design of vertical tube placement and annular distribution of furnace heating elements. It can be used for quenching, annealing, tempering heat treatment of small steel parts, as well as vertical CVD coating. The equipment can be operated in atmosphere state, vacuum state, can also be used as a common tubular furnace, suitable for university laboratories and scientific research institutes and other units.

Configuration

| 1. The heating element is annular distributed in the furnace, and the furnace tube is surrounded 360 degrees to improve the temperature uniformity in the furnace; | ||||||||||||||

Model | NBD-LT1700-80TI | ||||||||||||||

Electrical Spec | AC220V 1.8KW | ||||||||||||||

Tmax | 1700 ℃ | ||||||||||||||

Max working temps. | 1650 ℃ | ||||||||||||||

Heating rate | ≤ 20 ℃/min | ||||||||||||||

Heating length | 300mm | ||||||||||||||

Tube size | Φ80*1000mm | ||||||||||||||

Control system |

| 1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; | |||||||||||||

Temp Accuracy | +/- 1 ℃ | ||||||||||||||

Heating element | |||||||||||||||

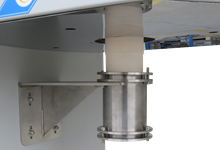

Sealing system |

|

|

| ||||||||||||

Vacuum degree: ≤10Pa (mechanical pump) | |||||||||||||||

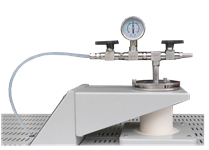

Pressure measurement & monitoring |

| The mechanical pressure gauge with damping oil is used to produce damping when the pressure fluctuates and reduce the pointer to swing back and forth. | |||||||||||||

Gas supply system |

| Float flowmeter is used to control the flow rate of gas, integrated with the equipment, and the leakage test has been carried out before leaving the factory. | |||||||||||||

Cautions | 1. When the equipment is in use, the reading of the absolute pressure gauge should not be greater than 0.15MPa to prevent equipment damage caused by excessive pressure. | ||||||||||||||

Service | 1 year warranty with lifetime support (The warranty does not include consumable parts, such as furnace tubes and sealing rings). | ||||||||||||||

推荐产品

Double temperature rapid annealing slide furnace

Intelligent tube furnace 1700℃

Glove box + anaerobic anhydrous molten salt plating furnace

Steam generator for tube furnaces

Roll to roll two-dimensional material preparation system

Cold wall intermediate frequency induction melting furnace

Vertical tube furnace (Type II)

High pressure and high vacuum rotary pendulum sintering furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China