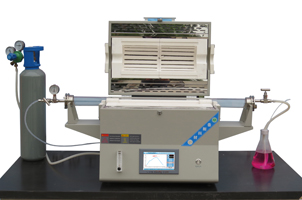

Vertical tube furnace (saturated steam)

Release time: 2021-03-29 10:27:22 Number of views: 2343

Equipment introduction:

Vertical tubular furnace adopts vertical tube structure design, which can be used for quenching, annealing, tempering heat treatment of small steel parts, as well as vertical CVD coating. The equipment can operate under atmosphere condition. Can also be used as a common tube furnace, suitable for university laboratories and research institutes and other units. This equipment can meet the saturated water vapor can carry out a variety of experiments.

Configuration details

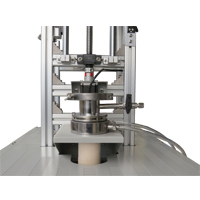

| 1. Heating elements are distributed around the furnace chamber, fully surrounding the furnace tubes at 360 degrees, enhancing temperature uniformity inside the furnace; 2. High-purity Al2O3 fiber refractory insulation material, with superior insulation effect, effectively reducing the power consumption of the equipment; 3. The furnace body adopts a double-layer air-cooling structure, which helps to reduce the surface temperature of the shell; 4. Intelligent PID fuzzy temperature control is used, with a 7-inch touch screen for centralized operation, capable of intuitively displaying "time-temperature" curves; 5. An integrated water-cooled flange is adopted to prevent the flange from overheating and damaging the sealing ring, fully ensuring the equipment's airtightness; 6. Self-developed electromagnetic hoist release technology is used to achieve rapid quenching treatment of materials; | |||||||||||

Product Model | NBD-LT1700-50TI | NBD-LT1700-60TI | NBD-LT1700-80TI | |||||||||

Electrical specifications | AC220V 4.5KW | |||||||||||

Highest temperature | 1700 ℃ (<1hour) | |||||||||||

Continuous temperature | 1650 ℃ (continuity) | |||||||||||

Maximum heating rate | ≤20℃/min | |||||||||||

Heating zone length | 200mm | |||||||||||

Furnace tube size | Φ50*1000mm | Φ60*1000mm | Φ80*1000mm | |||||||||

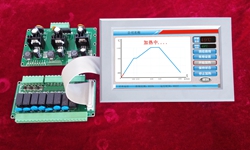

Control system |

| 1. Adopt fully automatic control method, with a touch screen for real-time display of various device data; 2. The experimental process is more intuitive and operations are more convenient; 3. Features include over-temperature alarm, open circuit prompt, and leakage protection. | ||||||||||

Temperature accuracy | +/- 1 ℃ | |||||||||||

Heating element |

| |||||||||||

Sealed system |

|

|

| |||||||||

Vacuum degree:≤10Pa(Mechanical pump) | ||||||||||||

Pressure measurement and monitoring |

| Use a mechanical pressure gauge with shock absorber oil to create damping when pressure fluctuates, reducing the back-and-forth movement of the needle. | ||||||||||

Gas supply system |

| Adopting a rotameter to control the gas flow rate, it is integrated with the equipment and has undergone leak testing before leaving the factory. | ||||||||||

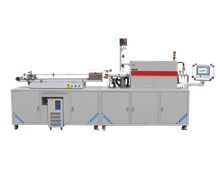

Steam generator |

| 1. Adopt a special vaporization structure to ensure stable steam generation; 2. Vaporization temperature is adjustable; 3. Liquid flow rate is controllable; 4. Equipped with a condensation system to prevent steam condensation and reflux; 5. Automatic liquid feeding, easy installation, compatible with tubular furnaces from various manufacturers. | ||||||||||

Electrical specifications | AC220V 400W | |||||||||||

Highest temperature | 200℃~400℃ | |||||||||||

High-precision peristaltic pump | 1. Speed range: 0.1·100rpm reversible; 2. Speed resolution: 0.1rpm; 3. Speed control method: membrane buttons; 4. Display method: 4-digit LED display of current speed or flow rate; 5. Reinforced PP material, corrosion-resistant; 6. Flow rate: 0.04-36ml/min; 7. Equipped with a full-speed button for quick emptying and filling; 8. Power failure memory function, timely saving of operating parameters. | |||||||||||

Control system | 1. Fuzzy PID temperature control, with high-brightness digital display; 2. Programmable multi-segment "time-temperature" curve setting; 3. Features over-temperature alarm, open-couple indication, and leakage protection. | |||||||||||

Temperature accuracy | +/- 1℃ | |||||||||||

Net weight | 15KG | |||||||||||

Precautions for using the equipment | 1. When using the equipment, the pressure inside the furnace tube must not exceed 0.125 MPa (absolute pressure) to prevent excessive pressure from causing damage to the equipment; 2. When using the equipment under high vacuum (10 to the power of -3 Pa), the operating temperature must not exceed 800°C. | |||||||||||

Service Support | 1-year warranty, lifetime support provided (warranty does not cover consumable parts such as furnace tubes and seals) | |||||||||||

Disclaimer: The product introductions on this site (including product images, descriptions, and technical parameters) are for reference only. There may be discrepancies between the stated content and actual conditions due to untimely updates. Please contact our customer service personnel for confirmation. The information provided on this site does not constitute any offer or commitment. Nobady Company reserves the right to improve and modify any information on the website without prior notice.

Related products

推荐产品

Vertical tube furnace 1500℃

High temperature tube furnace 1500℃

glass tempering furnace

2-way mass gas proportioner

Automatic hydrogen reduction furnace Type II

Lift type large capacity sintering furnace

Pilot scale molten salt electroplating furnace

Single temperature zone tube furnace 1200℃

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China