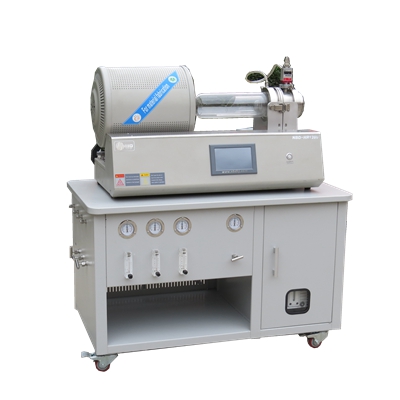

(non) metal evaporation purification system

Release time: 2024-09-04 15:20:25 Number of views: 1350

The evaporation purification system is highly integrated design of vacuum sintering and evaporation condensation, and the purification process is convenient and efficient. The evaporation component adopts high purity quartz liner to ensure that the material is not polluted by any; 360-degree ring heating, uniform distribution of temperature field; Unique overall inclined structure design, evaporation, condensation barrier-free.

Configuration details

| 1. High-purity quartz chamber, unique inclined evaporation condensation channel; 2. High-purity Al2O3 fiber refractory insulation material, energy-saving and consumption reduction; 3. High-purity alumina coating can extend the service life of heating elements; 4. Alumina tube plugs can help you establish a perfect temperature gradient inside the tube. | ||||||

Product Model | NBD-VAH1200-20TIF-ZL-3C | ||||||

| Electrical specifications | AC220V 3.5KW | ||||||

Reachable temperature | 1200 ℃ (<1小时) | ||||||

Continuous temperature | 1150 ℃(连续) | ||||||

Maximum heating rate | ≤ 20 ℃/分钟 | ||||||

Furnace heating chamber dimensions | φ240*210mm | ||||||

| Quartz jar size | Φ200-φ50-620mm长 | ||||||

| Quartz jar | 约6L | ||||||

| Stainless steel cooling tank capacity | 约9L | ||||||

| Furnace body clear dimensions | 长980*深650*高590mm | ||||||

| Equipment water cooling pipe size | φ10mm | ||||||

| Furnace tilt angle | 3度 | ||||||

| Protection function | The device is equipped with a water flow switch, which automatically stops heating when the water supply is interrupted. | ||||||

Sealed component |

| 1. Aviation aluminum furnace door; 2. High-temperature resistant silicone rubber ring; 3. High-purity quartz door plug, filled with alumina fiber inside. | |||||

| Condensing system |  | Double water-cooling structure, with inlet and outlet gas port circuit design. | |||||

Control system |

| 1. Can pre-store 15 temperature curves, avoiding the hassle of repeated settings for different experimental processes; 2. The experimental process is more intuitive, and operation is more convenient; 3. NBD-101E embedded operating system with bilingual (Chinese and English) graphical interface, 7-inch true color touch screen input, intelligent human-computer dialogue mode, nonlinear sample temperature correction; 4. Features over-temperature alarm, open-couple prompt, leakage protection, and other functions. | |||||

Temperature control accuracy | +/- 1 ℃ | ||||||

Heating element |

| Mo-doped Fe-Cr-Al alloy | |||||

Pressure measurement and monitoring |

| Use a mechanical pressure gauge with shock absorber oil to create damping when the pressure fluctuates, reducing the back-and-forth movement of the pointer. | |||||

Net weight | 约150KG | ||||||

Precautions for using the equipment | 1. When the furnace temperature of the equipment is ≥300℃, it is prohibited to open the furnace to avoid injury; 2. During the use of the equipment, the pressure inside the furnace tube must not exceed 0.125MPa (absolute pressure) to prevent excessive pressure from damaging the equipment; 3. When used under vacuum, the operating temperature of the equipment must not exceed 800℃. 4. The internal pressure of the gas cylinder is relatively high. When introducing gas into the furnace tube, a pressure reducing valve must be installed on the gas cylinder. It is recommended to purchase a small pressure reducing valve for experimental use, with a range of 0.01MPa-0.15MPa, which will be more precise and safe when in use. 5. When the furnace body temperature is higher than 1000℃, the furnace tube must not be in a vacuum state; the pressure inside the furnace tube should be equivalent to atmospheric pressure, maintaining a normal pressure state; 6. The long-term use temperature of high-purity quartz tubes should be ≤1100℃ 7. During heating experiments, it is not recommended to close the exhaust valve and inlet valve at the flange end of the furnace tube. If it is necessary to heat the sample with the gas valves closed, the pressure gauge reading must be monitored at all times. If the absolute pressure gauge reading exceeds 0.15MPa, the exhaust valve must be immediately opened to prevent accidents (such as furnace tube rupture or flange flying out). | ||||||

Service Support | 1-year warranty, lifetime support provided (warranty does not cover consumable parts such as furnace tubes and seals) | ||||||

Disclaimer: The product introduction content on this site (including product images, product descriptions, technical parameters, etc.) is for reference only. There may be certain discrepancies between the stated content and the actual situation due to untimely updates; please contact our customer service personnel for confirmation. The information provided by this site does not constitute any offer or commitment. Nobodi Company reserves the right to improve and modify any information on the website from time to time without prior notice.

推荐产品

Vertical vacuum atmosphere furnace(clean type)

Graphite heater furnace

Microwave muffle furnace

Vertical HVPE single crystal growth system

CVD system HR1200-110TID3F

Intelligent muffle furnace (4L) 1200℃

Button type battery slicer

Multi channel gas self-control controller

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China