Automatic feed and feed hydrogen absorption sintering furnace

Release time: 2021-01-07 10:01:51 Number of views: 2095

Equipment introduction:

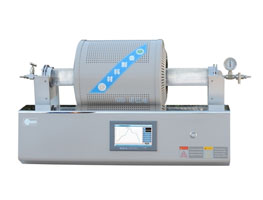

The NBD-RT1200-200T22DZ automatic inlet and outlet hydrogen absorption material sintering furnace is mainly designed for hydrogen absorption material to complete the requirement of hydrogen absorption through high temperature sintering under the conditions of no oxygen and high pressure and high vacuum.

The overall use of international advanced manufacturing technology, from the aesthetic art point of view according to the human safety point of view. The furnace lining is made of high-purity alumina lightweight fiber material, and the control system adopts advanced PLC+ touch screen control system, which makes the operation more simple and convenient. The control mathematical model adopts advanced PID self-learning fuzzy control to keep the temperature control accuracy at ±1℃.

This equipment is a high vacuum sintering furnace, the highest vacuum degree up to 8.0*10-2Pa, the highest sintering temperature 800℃, and has rotation, lifting and other functions; At the same time, through the high-precision pneumatic valve, strict process control design, special materials and processing technology and other multiple safety protection measures to ensure that under the premise of fully meeting the experimental requirements, to ensure the safety of equipment and operators.

Configuration

| 1, the control system adopts advanced PLC+ touch screen control system, the operation is more simple and convenient. The control mathematical model adopts advanced PID self-learning fuzzy control to keep the temperature control accuracy at ±1℃.

| |||||||

| Model | RT1200-200T22DZ | |||||||

Electrical Spec. |

Three-phase 380V; 50HZ | |||||||

Tmax | 800℃ | |||||||

Rated power | 18.0KW | |||||||

thermocouple | Type K thermocouple (400mm) | |||||||

Size of heating zone | φ250*870mm | |||||||

| Furnace tube material | 310S stainless steel | |||||||

Effective working area of furnace tube | φ187*600mm | |||||||

Furnace tube volume | 24L | |||||||

| Transfer tank volume | 5L | |||||||

| Material sintering Angle | -6 degrees (corresponding material 2L) | |||||||

angle of inclination | -31 degrees (discharge) ~11.7 degrees (feed) | |||||||

Furnace tube rotation speed | 1~4 R/min | |||||||

Maximum pressure resistance of furnace tube at normal temperature | 5Mpa | |||||||

Maximum working pressure of furnace tube at normal temperature | 4Mpa | |||||||

Ultimate pressure resistance of transfer tank | 1Mpa | |||||||

| Maximum vacuum | 8.0*10-2Pa | |||||||

Furnace size | L2600×D900×H1540mm | |||||||

Recommended heating rate | 10℃/min | |||||||

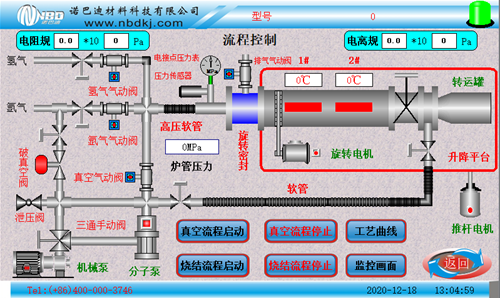

| control system | 1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; 2, can be reserved sintering, to achieve unattended sintering process curve sintering; | |||||||

| Main monitoring interface |  | |||||||

| Mechanical operating interface |  | |||||||

Temp. Accuracy | +/- 1 °C | |||||||

Local picture |

|

| ||||||

Net weight |

Approx.550KG | |||||||

Cautions | 1. Users are not allowed to modify the equipment without permission; | |||||||

Service | One year limited warranty with lifetime support (warranty does not include consumable parts) | |||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

|  |  | |

|  |  |  |

推荐产品

CMT furnace sliding rail tube furnace 1200℃

Universal testing machine with heating furnace (Type B)

Large size tube atmosphere vacuum furnace

Automatic hydrogen making machine H300

Split pit furnace for glove box

Thermal insulation refractory product

CVD system T1700-XTIG2Z

4C vacuum pump

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China