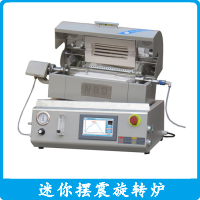

High pressure and high vacuum rotary pendulum sintering furnace

Release time: 2021-01-07 09:00:55 Number of views: 1481

Equipment introduction:

NBD-RT1200-200T22ZD rotary furnace with high temperature, high pressure and high vacuum automatic feeding and discharging adopts international advanced manufacturing technology as a whole, designed from the perspective of aesthetics and art according to the perspective of human safety. The furnace lining is made of high purity alumina light fiber material, and the control system is made of advanced PLC+ touch screen control system, which makes the operation more simple and convenient. The control mathematical model adopts advanced PID self-learning fuzzy control, which keeps the temperature control accuracy at ±1℃. This equipment is a high vacuum sintering furnace, the highest vacuum degree up to 8.0*10-2Pa, the highest sintering temperature 800℃, and has rotation, lifting and other functions.

1, The control system adopts advanced PLC+ touch screen control system, the operation is more simple and convenient. The control mathematical model adopts advanced PID self-learning fuzzy control, which keeps the temperature control accuracy at ±1℃. Model NBD-RT1200-200T22DZ Electrical Spec 3-phase 380V;50HZ Tmax 800℃ Rated power 18.0KW Thermocouple type Type K thermocouple (400mm) Size of heating zone φ250*870mm Tube material 310S Stainless Steel Effective working area of furnace tube φ187*600mm Furnace tube volume 24L Transfer tank volume 5L Material sintering Angle -6 degrees (corresponding material 2L) Angle of inclination -31 degrees (discharge) ~11.7 degrees (feed) Furnace tube rotation speed 1~4 R/min Maximum pressure resistance of furnace tube at normal temperature 5Mpa Maximum working pressure of furnace tube at normal temperature 4Mpa Maximum pressure resistance of transfer tank 1Mpa Maximum vacuum 8.0*10-2Pa Furnace dimension L2600×D900×H1540mm Recommended heating rate 10℃/min Control system 1. Sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; Main monitoring interface Mechanical operating interface Temp Accuracy ±1℃ Partial picture Net weight Approx.550KG autions 1. Users are not allowed to modify the equipment without permission; 2. It is forbidden to place toxic and harmful chemical products and high-pollution articles into the furnace chamber; Service One year limited warranty with lifetime support (warranty does not cover consumable parts).

2. The system is designed with multiple protection functions to ensure the safety of operators and equipment to the greatest extent. The system functions are highly integrated to reduce the labor intensity of operators to the greatest extent.

3. The high vacuum rotary tube furnace can rapidly rise and cool down, and can realize automatic feeding and unloading, which is convenient for customers to load, fire and observe the materials. The automatic rotation of the furnace tube can make the materials keep churning and stirring in the constant temperature zone, so that the materials are fired more evenly.

2. Can be booked sintering, unattended sintering process curve sintering;

3. Real-time display of sintering power and voltage information and record sintering data, and can be exported to achieve paperless record;

4. It can realize remote control and real-time observation of equipment status;

5. Temperature correction: the difference between the main control temperature and the sample temperature, and the whole sintering process is nonlinear correction.

3. When the temperature of the furnace surface is heated continuously, the local temperature may be over 70℃. Please do not touch the surface of the furnace directly with your body to avoid damage;

4. Please cut off the power supply when cleaning the furnace body and wipe it with a wet cloth.

5. Do not click on the display screen of the control unit/with sharp objects, so as to avoid screen damage and physical injury;

6, the system is equipped with exhaust fan, exhaust fan is used to control the system temperature, to ensure the safety of the system, do not block the top cover of the furnace body;

7, this product should avoid liquid and oil, can not be used in the liquid medium work, can only be used in the gas working medium. The gas must be clean and dry, free of particulates and moisture. Otherwise, it is necessary to install filters and dryers in the gas path to meet the requirements. Pay attention to keep the controller air path clean, once polluted, will seriously affect the accuracy of the product.

Configuration

| 1, The control system adopts advanced PLC+ touch screen control system, the operation is more simple and convenient. The control mathematical model adopts advanced PID self-learning fuzzy control, which keeps the temperature control accuracy at ±1℃. | |||||||

Model | NBD-RT1200-200T22DZ | |||||||

Electrical Spec | 3-phase 380V;50HZ | |||||||

Tmax | 800℃ | |||||||

Rated power | 18.0KW | |||||||

Thermocouple type | Type K thermocouple (400mm) | |||||||

Size of heating zone | φ250*870mm | |||||||

| Tube material | 310S Stainless Steel | |||||||

Effective working area of furnace tube | φ187*600mm | |||||||

Furnace tube volume | 24L | |||||||

| Transfer tank volume | 5L | |||||||

| Material sintering Angle | -6 degrees (corresponding material 2L) | |||||||

Angle of inclination | -31 degrees (discharge) ~11.7 degrees (feed) | |||||||

Furnace tube rotation speed | 1~4 R/min | |||||||

Maximum pressure resistance of furnace tube at normal temperature | 5Mpa | |||||||

Maximum working pressure of furnace tube at normal temperature | 4Mpa | |||||||

Maximum pressure resistance of transfer tank | 1Mpa | |||||||

| Maximum vacuum | 8.0*10-2Pa | |||||||

Furnace dimension | L2600×D900×H1540mm | |||||||

Recommended heating rate | 10℃/min | |||||||

| Control system | 1. Sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; 2. Can be booked sintering, unattended sintering process curve sintering; 3. Real-time display of sintering power and voltage information and record sintering data, and can be exported to achieve paperless record; 4. It can realize remote control and real-time observation of equipment status; 5. Temperature correction: the difference between the main control temperature and the sample temperature, and the whole sintering process is nonlinear correction. | |||||||

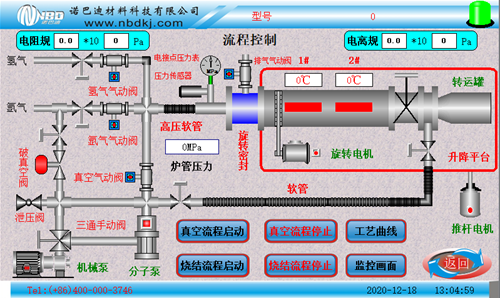

| Main monitoring interface |  | |||||||

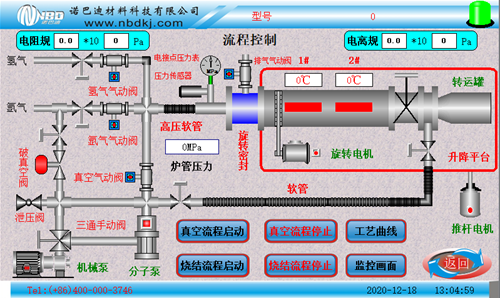

| Mechanical operating interface |  | |||||||

Temp Accuracy | +/- 1 °C | |||||||

Partial picture |

|

| ||||||

Net weight | Approx.550KG | |||||||

Cautions | 1. Users are not allowed to modify the equipment without permission;

| |||||||

Service | One year limited warranty with lifetime support (warranty does not cover consumable parts). | |||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

|  |  | |

|  |  |  |

推荐产品

NBD-103(B) Vacuum system

High temperature elastic modulus tester heating system

Rf independent system

Hydrogen reduction furnace with smooth bore

RTP rapid steaming sintering furnace

1200°C Vacuum Atmosphere Chamber Furnace(27L)

Intelligent Chamber Furnace (7.2L) 1200°C

Double temperature rapid annealing slide furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China