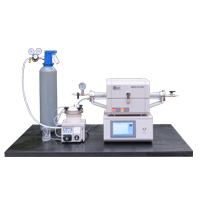

Ion sputtering device

Release time: 2020-11-20 22:51:04 Number of views: 6784

Equipment introduction:

The NBD-LJ13 ion sputtering instrument is designed for the sample production of scanning electron microscope. It has the characteristics of simple structure, intuitive operation and convenient. It can be used for ion sputtering of SEM samples without high vacuum degree, and can be used as the basic equipment of SEM sample coating.

Configuration Details (Product model: NBD-LJ13)

| Main characteristics: 1. 4C quiet vacuum pump is adopted to reduce noise in all aspects and improve experimental experience; | |

| Control Panel: Vacuum meter: The unit of measurement of vacuum degree mmHg or Pa is engraved on the dial, which can conveniently read the vacuum degree in the working room; Ammeter: display sputtering current value unit (mA); Fine-tuning valve (charging valve) : used for charging to the working room; Test button: with needle valve setting, in order to obtain satisfactory sputtering current value (less than 10mA); Sputtering button: When the current of the "experiment" button is less than 10mA, you can press the "Sputtering" button to carry out ion sputtering on the sample; Time setting switch: control ion sputtering time, timing switch 10 ~ 110S; Power switch: control instrument chassis power supply and mechanical pump on and off. | |

| High purity quartz vacuum chamber Φ130 (inner 118) *130mm | |

Electrical Spec | AC220V 120W | |

Chamber size | Φ130 (inner 118) x 130mm | |

Sample table size | Φ42mm | |

Sample table adjustable height | Sample table adjustable height: 75mm | |

Sample temperature | <35~50℃ | |

Suitable target material | Precious metals AU, Pt, Pd alloy AU-Pt, AU-Pb conventional metals Cu, W, Ag, Cr, etc. | |

Sputtering velocity | Generally speaking, the thickness of the metal used to scan the sample is 100-300A. The thickness is determined by the empirical method, which can be obtained by the following formula d = KIVT Where: d: is the coating thickness (unit A) K: Is a constant, depending on the sputtered metal and the gas (K is 0.17 for gold and argon, and 0.07 for gold and air), and the distance between the target and the sample I: is the constant ion current (unit mA) V: voltage applied (unit kv) T "" is the time (unit s). For example, gold targets and argon are used, l is 8mA,T is 100 seconds, and V is 1KV Then, d = KIVT = 0.17 ×8×l×100 = 136A That's 1.36 A per second The speed of sputtering depends on the cleanliness of the sputtering system itself, so it is important to protect the cleanliness of the studio. The sputtering speed of other metal targets, for example, platinum target is about half the speed of gold target, gold-platinum target has a very close to the gold target sputtering speed. | |

Cautions | 1. Replacement of target material First pull out the high pressure and ground plug on the sputtering cover plate, take down the sputtering cover plate, loosen the three top wires, take down the protection plate, and then screw down the pressure ring to replace the new target. 2. Vacuum studio cleaning The chamber studio is cleaned with anhydrous ethanol and acetone to ensure that the system can work normally. 3, needle valve use After the needle valve is closed, reverse twist it for two turns to prevent the needle from not bouncing back flexibly for a long time. If you do not vent to the studio when opening the needle valve, please screw the needle valve button to the end and then open it again. | |

Standard configuration | 1.NBD-4C vacuum pump; 2 Gold target 1: Φ58*0.12 3. A copy of manual (optional molecular pump) | |

Service | One-year warranty, lifetime service; | |

Net weight | 25KG | |

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

|

|

推荐产品

Ultrasonic atomizing CVD tube furnace

3-way float gas proportioner

Glove box matching transition furnace

High temperature vacuum induction furnace

Multi channel liquid gas-phase generator

Glove box + anaerobic anhydrous molten salt plating furnace

Medium sized high-temperature vacuum atmosphere box furnace

Production type swing rotary converter

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China