High temperature and high pressure tube furnace

Release time: 2020-09-30 23:49:37 Number of views: 3879

Equipment introduction:

NBD-HP1200 mini high temperature and high pressure tubular furnace, high pressure solenoid valve installed on the flange, pressure sensor and analog quantity safety protection. Three more layers of security, so you don't have to worry. When the pressure in the chamber is higher than the set value, the electromagnetic vent valve will automatically open the exhaust, so that the pressure in the tube reaches the set value. This type of sample can be heat treated in the high-pressure atmosphere gas environment, the highest temperature can reach 1150℃. Suitable for the exploration and research of superconductivity and dielectric materials.

Configuration

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

Configuration

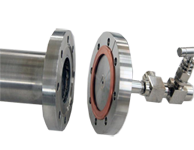

1. Three layers of security protection let you work in peace; 2. High ring heater, uniform temperature field; 3. Modular structure, durable and easy to maintain; 4. Stable voltage setting, safe and reliable; 5. One key operation is simple and convenient, pre-stored 15 working curves, whatever you want; 6. Real-time sintering temperature and power monitoring, safety and power saving Model NBD-HP1200-2350TIY-D Electrical Spec AC220V 1.5KW lowable pressure Temperature varies with air pressure. Please refer to the table below for details: furnace temperature Maximum cavity pressure ≤ 600°C ≤ 24MPa ≤ 800°C ≤ 20MPa ≤ 900°C ≤ 12MPa ≤ 1000°C ≤ 6MPa ≤ 1100°C ≤ 4MPa High temperature and high pressure pipe belongs to consumables, when you find it deformation, please replace it in time. Cavity specification 1. Size: sample constant temperature zone Φ23mm *120mm (more specifications, put forward the demand, for your choice) furnace construction 1. Can open double-layer structure, conducive to the need for rapid cooling customers, shell surface temperature is less than 60℃ Gas and crucible are available 1. Oxidation, protective atmosphere and inert gases, such as N2, Ar and He. furnace tube for sintering, do not put the sample directly in the high-temperature and high-pressure tube without a crucible. Control system 1. 15 temperature curves can be pre-stored, and 30 sections of "temperature-time" axis can be set for each curve, avoiding the trouble caused by repeated setting of different experimental processes; 2.NBD-101E embedded operating system Chinese and English interchange graphical interface, 7 inch true color touch screen input, intelligent man-machine dialogue mode, real-time heating power display, non-linear pattern temperature correction; 3. With over temperature and over pressure alarm, broken couple protection, leakage protection, differential pressure relief and other functions. 4. The first layer of protection: when the pressure value exceeds the customer set, automatically open the solenoid valve pressure relief; The second layer of protection: when the exhaust pipe is blocked or the solenoid valve is damaged and the pressure is still rising beyond the pressure relief value, the temperature point system automatically sets the limit pressure, the equipment stops heating; The third layer of protection: when the pressure is inaccurate due to the pollution of the digital sensor, or the program control system fails, the pressure continues to rise. When it reaches the upper pressure value set by the pressure relay of the safety analog signal, the power supply is directly turned off. Temp Accuracy +/- 1℃ Dimensions & Weight 800*450*350mm ; 45KG Heating element Ferric chromium alloy doped molybdenum Pressure detection & control 1. The high pressure chamber is installed with a pressure sensor, and connected with the control system, real-time display set pressure value, the solenoid valve will automatically open and deflate, and the chamber pressure is maintained within the set pressure range. The maximum automatic relief pressure that the solenoid valve can bear is 15Mpa. When the pressure is higher than 15Mpa, the solenoid valve cannot be used for pressure relief. The series needle method should be closed and the manual method should be used for pressure relief. Sealing of flange 1. CF flange structure drawing is as follows (using copper sealing ring) and a high pressure valve is installed at each end of the flange, and the right valve is equipped with a pressure gauge. 3. The flange is sealed with oxygen-free copper seal ring; Cautions The company's high temperature and high pressure furnace tubes are made of high temperature alloy steel, the highest temperature resistance of 1150℃, good ductility. When the air pressure inside the cavity exceeds the maximum tolerable value (exceeding the long-term strength of the alloy tube) due to misoperation, the alloy tube will creep and bulge at the weak place first, then crack will appear to release the gas. No high pressure cracking risk.

The 2.1/4NPS internal thread interface is installed in the furnace tube air inlet, supporting high pressure air supply pipe

Note: High temperature and high pressure reaction tubes are consumables and are not covered by warranty.

2. Nano high temperature alumina coating on the surface of the inner furnace can improve the heating efficiency of the equipment.

3. The furnace body is designed to be open, so as to load the material and replace the furnace tube.

2. In order to avoid sample pollution, it is best to wrap the sample with gold foil or nickel foil into alumina or quartz boat, and then put it into the

2. The high pressure relief solenoid valve is installed on the flange. When the pressure in the furnace tube is higher than the

The 2.1/4NPS internal threaded connection is installed on the furnace pipe flange,

4. Optional torque wrench to avoid excessive tightening flange1 year warranty with lifetime support (The warranty does not include consumable parts, such as furnace tubes and sealing rings).

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

推荐产品

PECVD system

Uniform temperature heating platform

1200 ℃ large capacity intelligent box furnace (80L)

Variable frequency tablet press

CVD system T1500-XTID3Z

Pilot scale molten salt electroplating furnace

1200°C Vacuum Atmosphere Chamber Furnace(27L)

Heat resistant material test furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China