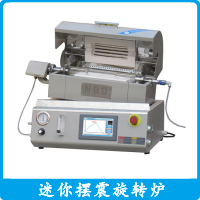

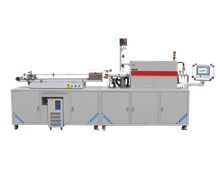

Horizontal vacuum furnace

Release time: 2020-08-28 11:42:12 Number of views: 2324

Equipment introduction:

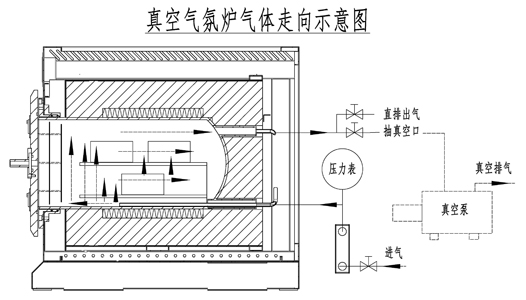

The VAH horizontal vacuum furnace is used for sample preparation of various materials in a clean environment. The product uses annular electric heating wire to heat uniformly outside the high purity quartz vacuum chamber, which has high thermal efficiency, fast heating speed and good temperature uniformity. The protective atmosphere is evenly circulated inside, forward and out, and the sealing parts are made of high-temperature sealing rings and water-cooled stainless steel sealing system, which is safe and reliable. The equipment has complete automatic touch screen operation performance, and has over temperature, break and low water pressure alarm function.

Configuration

| Equipment features: | ||||||

Model | NBD-VAH1200-20TIF | ||||||

Electrical Spec | AC220V 4KW | ||||||

| System vacuum | 5-10Pa | ||||||

Tmax | ≦1100 ℃ | ||||||

Heating rate | ≤ 20 ℃/min | ||||||

Heating zone size | Ø190mm *200 | ||||||

Cavity septum | double-deck | ||||||

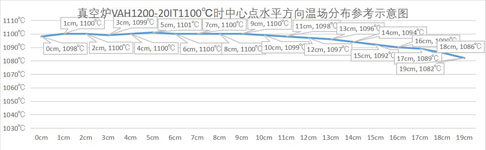

Temperature field distribution |

| As shown in the figure: This is the temperature zone diagram of the equipment for reference only | |||||

Control system |

| 1. 15 temperature curves can be pre-stored to avoid the trouble caused by repeated Settings of different experimental processes; | |||||

Temp Accuracy | +/- 1 ℃ | ||||||

Heating element |

| Annular heating Mo doped Fe-Cr-Al alloy heater, the temperature field is uniform and reliable | |||||

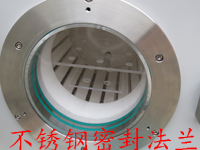

Sealing system |

|

|

| ||||

Vacuum degree: ≤10Pa (mechanical pump) | |||||||

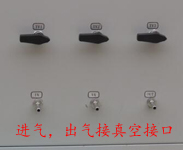

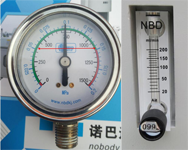

Gas supply system and pressure measurement |

| Mechanical pressure gauge with damping oil, and 1 small flow high-precision float flowmeter. | |||||

Net weight | 20KG | ||||||

Cautions | 1. When the equipment is used, the pressure in the furnace tube shall not exceed 0.15MPa (absolute pressure) to prevent damage to the equipment caused by excessive pressure; | ||||||

Service | 2-year limited warranty with lifetime support (warranty does not cover consumable parts such as quartz cavities and O-rings). | ||||||

Disclaimer:

The content of product introduction (including product pictures, product descriptions, technical parameters, etc.) is for reference only. Due to the delay in updating, there may be some differences between the said content and the actual situation. Please contact our customer service staff for confirmation. The information provided on this site does not constitute any offer or commitment, and Nobadi will improve and modify any information on this site from time to time without prior notice.

Related products

| |||

推荐产品

Constant pressure vacuum rotary pendulum sintering furnace

Automatic hydrogen reduction furnace Type II

Four-way float proportioning gas supply tank

Observation window muffle furnace

Float + vacuum system mobile platform

.png)

3-heating zone type tube furnace 1200℃

Open type high flux four-channel tube furnace

glass tempering furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China