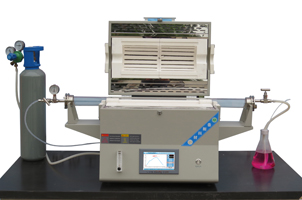

Homogeneous oxidation diffusion furnace (Type I)

Release time: 2020-08-26 00:06:27 Number of views: 3516

Equipment introduction:

Homogeneous temperature oxidation diffusion furnaces are used to diffuse, oxidize, anneal, alloy and sinter wafers in semiconductor devices, discrete devices, optoelectronics, power electronics, solar cells and large-scale integrated circuit manufacturing. They can be used in 2-8 inch process sizes.

Configuration

| Equipment features: 1. Uniform temperature field, length and accuracy of constant temperature zone: 300 ~ 1250mm 800~1200℃±1℃ 2. With powerful software functions, NBD-101EP embedded operating system, users can easily modify the process control parameters, and can display a variety of process state at any time; Equipped with fault self-diagnosis software; 3. The program can realize manual/automatic work. After power failure or stoppage, restart can be manually heated according to the process, saving the process time; 4. With a variety of process pipelines, convenient for users to choose; 5. The cold end detects the ambient temperature for temperature compensation, so as to avoid the influence of ambient temperature change on the furnace temperature and avoid interlayer interference; 6. Multiple groups of PID parameters can be stored for system operation call function, with multi-point temperature compensation 7. Gas flow adopts digital precision control, adopts analog signal closed-loop control, strong and weak electricity are separated, and all kinds of data interaction adopts standard bus to improve anti-interference ability and ensure data safety; Gas opening has the function of slow start; 8. With a variety of alarm functions and safety protection functions; 9. Automatic adjustment of constant temperature zone, cascade control, can accurately control the actual process temperature of the reaction tube; 10. The pressure automatic adjustment technology introduces the pressure parameter into the crystal silicon oxidation process, effectively reducing the interference of the tail exhaust on the process and reducing the process fluctuation caused by the exhaust air. | ||||||

Outer diameter of process pipe can be configured | Furnace tube outer diameter 152mm suitable for 3 "; Furnace tube outer diameter 252mm suitable for 6 "; | ||||||

Temperature control range | 300~1150 ℃ | ||||||

Length and accuracy of constant temperature zone | 300~1250mm(Subject to customer requirements) 300~800 ℃±1.5℃, 800~1100 ℃±1℃ | ||||||

Controllable rise and fall rate | Heating rate: ≦15℃/min Cooling rate ≦5℃/min | ||||||

quantity of heating zones | 3-zone,4-zone,5-zone,6-zone(customizable) | ||||||

Feeding mode | hand-operated feed | ||||||

cooling system | Water cooling 2-4Kgf/cm2, 8L/min; + upper exhaust air cooling ≈25m3/min; | ||||||

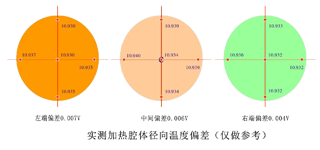

Radial temperature distribution |

| ||||||

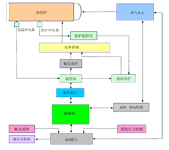

Control system | 1. Sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; 2. Can be booked sintering, unattended sintering process curve sintering; 3. Real-time display of sintering power and voltage information and record sintering data, and can be exported to achieve paperless record; 4. It can realize remote control and real-time observation of equipment status; 5. Temperature correction: the difference between the main control temperature and the sample temperature, and the whole sintering process is nonlinear correction. |

| |||||

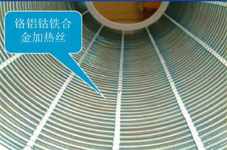

heating chamber |

| High quality heating wire: KANTHAL and HRE Insulation material: crystal fiber, etc Insulator: high purity corundum, spacing according to temperature field adjustment Port transition ring: alumina fiber vacuum forming. Warm zone: 3, 4, 5, 6 segments | |||||

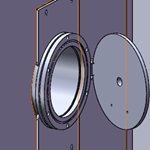

Vacuum sealing system |

| ||||||

Vacuum degree: ≤10Pa (mechanical pump) | |||||||

Gas supply system |

| Mass flowmeter is used to control the gas flow rate, which is integrated with the equipment.; | |||||

Optional item | 1. Discharge port detoxification gas cabinet; 2, clean discharge platform; 3, automatic quartz pulp push and pull boat mechanism. | ||||||

Cautions | 1, the sampling piece must be loaded with asbestos gloves, using quartz devices to break carefully; 2, choose the appropriate quartz boat, take out the clean quartz plate and quartz retractor; 3. The installation sample piece is inserted into the groove of the quartz boat, and the quartz boat is pushed into the furnace tube to the constant temperature zone with the quartz hook; 4. The pressure inside the furnace shall not exceed 0.15MPa (absolute pressure) to prevent danger caused by excessive pressure; 5. When used under high vacuum), the operating temperature of the equipment shall not exceed 1000℃. | ||||||

Service | One year limited warranty with lifetime support (warranty does not cover consumable parts such as furnace tubes and seals). | ||||||

推荐产品

PECVD system

Intelligent tube furnace 1700℃

Multi channel gas self-control controller

Manual button battery sealing machine

High power PECVD system (Rotary Pendulum Vibration)

Mini mixing sintering furnace

Intelligent Sintering Furnace AISF System (Automatic Intelligent Sintering Furnace)

Single temperature zone tube furnace 1200℃

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China