Large denture waxing furnace

Release time: 2020-07-14 11:49:15 Number of views: 1926

Equipment introduction:

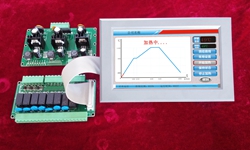

The flat design of this equipment not only greatly improves the proportion of space, but also separates the heating system and control unit reasonably and does not interfere with each other, which can ensure that the electric heating element and the whole circuit system keep safe and reliable working state in the high temperature environment. Very simplified classic design process, multi-layer alumina fiber sintering furnace (to prolong the life of the furnace several times), the touch screen control, man-machine dialogue, barrier-free communication, so that the operation is easier.

Configuration

| 1. The furnace volume is moderate, suitable for heat treatment of various materials; | ||

Model | NBD-M1200-20TI | ||

Electrical Spec | AC220V 4KW | ||

Tmax | 1200℃ | ||

Max working temps. | 1100℃ | ||

Heating rate | ≤20℃/min | ||

Chamber size | 200*200*300mm(12L) | ||

Control system |

| 1.NBD-101E embedded operating system English and Chinese interchange graphical interface, 7 inch real color touch screen input, intelligent man-machine dialogue mode, real-time heating power display, non-linear pattern temperature correction; | |

Temp Accuracy | +/- 1℃ | ||

Heating element |

| Mo-doped Fe-Cr-Al alloy | |

Net weight | 45KG | ||

Cautions | 1. When the furnace temperature of the equipment is greater than or equal to 300℃, it is forbidden to open the furnace to avoid injury; | ||

Service | 1 year warranty with lifetime support (the warranty does not cover consumable parts, such as furnace tubes and sealing rings). | ||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. Nobardi will improve and modify any information on this site from time to time without prior notice.

推荐产品

High magnetic induction quenching furnace

High temperature and high pressure tube furnace

Zirconia crystallizing furnace

Hydrogen reduction integrated sintering furnace (1500 ℃)

Microwave high temp muffle furnace

Program controlled large vacuum drying oven

CVD system O1200-XTID3F

Vertical eight channel high-throughput tube furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China