Medium denture waxing furnace

Release time: 2020-07-14 11:42:05 Number of views: 2017

Equipment introduction:

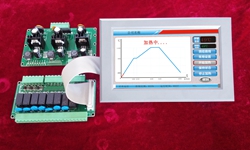

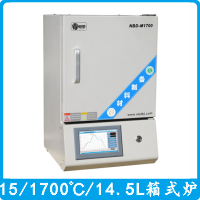

This equipment is designed to meet the needs of customer wax processing, is a cost-effective medium temperature sintering furnace. Very simplified classic design process, light alumina fiber sintering furnace, using touch screen control, man-machine dialogue, barrier-free communication, so that the operation is easier.

Configuration

| 1. The furnace volume is moderate, suitable for heat treatment of various materials; | ||

Model | NBD-M1200-15TI | ||

Electrical Spec | AC220V 3KW | ||

Tmax | 1200℃ | ||

Max working temps. | 1100℃ | ||

Heating rate | ≤20℃/min | ||

Chamber size | 150*150*150mm | ||

Control system |

| 1.NBD-101E embedded operating system English and Chinese interchange graphical interface, 7 inch real color touch screen input, intelligent man-machine dialogue mode, real-time heating power display, non-linear pattern temperature correction; | |

Temp Accuracy | +/- 1℃ | ||

Heating element |

| Mo-doped Fe-Cr-Al alloy | |

Net weight | 35KG | ||

Cautions | 1. When the furnace temperature of the equipment is greater than or equal to 300℃, it is forbidden to open the furnace to avoid injury; | ||

Service | 1 year warranty with lifetime support (consumable parts are not covered by warranty). | ||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. Nobardi will improve and modify any information on this site from time to time without prior notice.

Related products

推荐产品

Production type swing rotary converter

Press mold

Intelligent double temperature zone tube furnace 1700℃

Ultra high pressure and high temperature sintering furnace

Extended heating zone CVD slide tube type furnace

Glove box matching transition furnace

Constant temperature thermal fatigue testing machine

3-way mass gas proportioner

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China