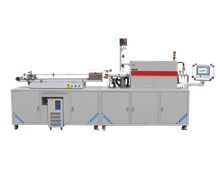

Multi temperature zone tube furnace

Release time: 2020-07-07 22:09:14 Number of views: 2600

Equipment introduction:

Multi-temperature zone CVD system integrated furnace, gas supply and vacuum system flexible combination, to meet all kinds of thin film deposition, is the semiconductor industry is the most widely used for deposition of thin film materials, including large area of insulation materials, as well as most metal materials and metal alloy materials. The complete set of CVD coating system of Nobardi is suitable for material laboratories, scientific research institutes, environmental science and other fields in universities.

| 1. Adopt high purity quartz or stainless steel furnace tube, excellent corrosion resistance and high temperature resistance; | ||||||||||||

Heating zone | 3-heating zone | 4-heating zone | 5-heating zone | 6-heating zone | |||||||||

Tube size | Ø25/Ø50/Ø60/Ø80/Ø100*1600mm | ||||||||||||

Max working temps. | ≤1150℃ | ||||||||||||

Heating zone selection | 200mm*3 200+300+200mm 200+400+200mm 300mm*3 300+400+300mm | 200mm*4 200+300+300+200mm 200+400+400+200mm 300mm*4 300+400+400+300mm | 200mm*5 300mm*5

| 200mm*6 300mm*6

| |||||||||

Heating rate | ≤20℃/s | ||||||||||||

Electrical Spec | AC380V 6~10KW | AC380V 8~14KW | AC380V 10~15KW | AC380V 12~18KW | |||||||||

Gas system (optional) | Float or mass flowmeter | ||||||||||||

quantity of inlet ports | 2、3、4(Multi-channel optional) | ||||||||||||

flow range | 20-250/20-800ml/min......(Multi-range option) 50/100/200/500sccm......(Multi-range option) | ||||||||||||

Range of working pressure difference | 0-0.15MPa | ||||||||||||

Low vacuum system (optional) | Model (vacuum pump) | NBD-3C/NBD-4C | |||||||||||

pumping rate | 3L/s or 4L/s | ||||||||||||

Inlet and exhaust port dimensions | KF16/25 | ||||||||||||

System vacuum | 3~5Pa (Limit vacuum of vacuum pump 6.2*10-2Pa) | ||||||||||||

operating ambient temp. | 5-40℃ | ||||||||||||

Electrical Spec | AC220V | ||||||||||||

High vacuum system (optional) | Model (vacuum pump) | NBD-103(A) | NBD-103(B) | ||||||||||

pumping rate | 110L/s | 600L/s | |||||||||||

vacuum gauge | Composite vacuum gauge | ||||||||||||

System vacuum | 4.310^-3Pa | 6*10^-4Pa | |||||||||||

operating ambient temp. | 5-40℃ |

| |||||||||||

Electrical Spec | AC 220V | AC 380V |

| ||||||||||

* Support non-standard customization, more models, welcome to call 400-000-3746 | |||||||||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

推荐产品

Automatic hydrogen reduction furnace Type II

Large capacity bottom-loading furnace

Liquid Vapor Phase Generator (Type II)

Openable vertical tube furnace 1200℃

glass tempering furnace

Large denture waxing furnace

Hydrogen reduction furnace with smooth bore

1200 ℃ CVD integrated machine

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China

ZS.png)