Ultra-high temp. heating furnace 2000℃

Release time: 2020-06-19 11:19:06 Number of views: 3942

Equipment introduction:

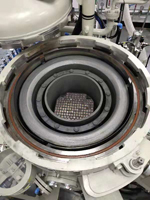

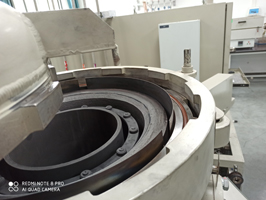

The vacuum furnace body consists of the furnace body, furnace cover and related accessories installed on it, furnace cover lifting mechanism, chassis, etc. The furnace body and cover have a uniform double-layer water-cooled structure, with a non-magnetic stainless steel plate for the inner layer and stainless steel for the outer layer. The furnace cover is equipped with imported two-color infrared thermometers, safety valves, pressure sensors, armored thermocouple interfaces, inflation valves, pressure vacuum gauges, electromagnetic vent valves, handrails, etc. for easy operation. The furnace body is equipped with explosion-proof devices, thermocouple interfaces for temperature measurement, and interfaces for power supply and vacuum pipelines. The furnace cover lifting mechanism completes the up and down opening and closing of the furnace cover, which is driven by hydraulic jacks. The smooth opening is manually achieved, and the chassis is used to support the entire vacuum chamber.

Configuration

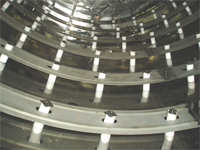

| 1. The double-layer air-cooled structure greatly reduces the surface temperature of the shell; 2. Equipped with a three-dip 4-baked graphite heater with excellent acid and corrosion resistance; 3. The use of graphite cotton felt made of refractory insulation material, small heat loss, help to reduce the use of equipment power; 4. Large sintering space, can be used for industrial production; 5. Touch screen operation, intuitive display of temperature curve; | ||||||||

Model | NBD-HR2000-80TI | NBD-HR2000-120TI | NBD-HR2000-160TI | NBD-HR2000-200TI | |||||

Electrical Spec | AC380V 22KW | AC380V 35KW | AC380V 40KW | AC380V 70KW | |||||

Tmax | 1800℃ | 1800℃ | |||||||

Heating rate | ≤20℃/min | ||||||||

Chamber size | Φ80*100mm | Φ120*150mm | Φ160*200mm | Φ200*300mm | |||||

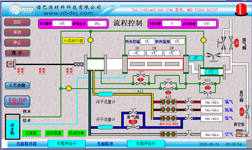

Control system |

| 1.NBD-101EP embedded operating system English and Chinese interchangeable graphical interface, 7 inch true color touch screen input, intelligent man-machine dialogue mode, real-time heating power display, non-linear pattern temperature correction; The experimental report is generated independently, and the experimental data is exported unlimited times. 2. 15 curves can be pre-stored, and 30 "time-temperature" nodes can be set for each curve, eliminating the process of repeatedly modifying curves; 3. It has the functions of over-temperature alarm, broken couple warning, leakage protection and so on. | |||||||

Temp Accuracy | +/- 1℃ | ||||||||

Heating element |

|

| |||||||

Excellent acid and corrosion resistance of graphite heater/tungsten molybdenum heater | |||||||||

Cautions | 1, always pay attention to the temperature of the furnace cover, furnace body, furnace bottom and water-cooled electrode, can not be hot, otherwise to stop heating, check whether the water is smooth. 2, if the vacuum degree is not pumped, it should be checked whether the oil in the diffusion pump is oxidized, and whether the mechanical pump is aging, such as aging should be replaced in time. 4, when filled with protective gas, attention should be paid to the value of the vacuum pressure gauge, which can not exceed the positive pressure (generally 2-3 cells below 0 and about -50Pa, the furnace is still negative pressure). It should be noted that the gas has the characteristics of thermal expansion, if close to the positive pressure, you can open the mechanical pump and pre-extraction valve to remove part of the gas. 5, when loading, be sure not to touch the graphite heating body (saw seam), because the heating body is fragile after burning, causing unnecessary losses. 6, usually should pay attention to the furnace, outside the furnace cleaning, vacuum valve maintenance work. 7, after opening the water pump should pay attention to check whether each valve is fully opened, and the connected water pipe without dripping phenomenon, if any should be eliminated in time. | ||||||||

Service | 1 year warranty with lifetime support (warranty does not cover consumable components such as furnace tubes and seals). | ||||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

推荐产品

Vacuum molten salt electrolysis furnace

Intelligent tube furnace 1700℃

MINI muffle furnace ( drop down door)

well type furnace G1200-15TI

Ultra high pressure and high temperature sintering furnace

Push-pull tube sintering furnace

PECVD system

Crucible for zirconia sintering

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China