Meltblowout cloth nozzle anaerobic cleaning furnace 1200℃

Release time: 2020-05-02 22:21:38 Number of views: 3746

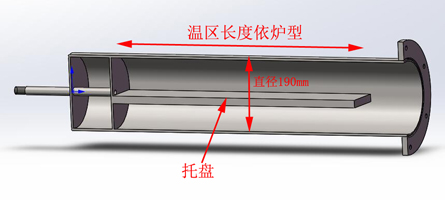

| 1. The blocked sprinkler head is placed upside down in the tray of the furnace tube to feed into the nitrogen atmosphere for protection, and the outlet end is ensured to be free of obstruction; | |||||||

Model | NBD-T1000-200TIF | NBD-T1000-200T22F | NBD-T1000-200T33F | |||||

Electrical Spec | AC380V 8KW | AC380V 12KW | AC380V 18KW | |||||

Tmax | 1000 ℃ | |||||||

Max working temps. | 900 ℃ | |||||||

Heating rate | ≤ 20 ℃/min | |||||||

Heating length | 400mm;Suitable for 300 sprinkler heads | 600mm;Suitable for 450 sprinkler heads | 900mm;Suitable for 600,800 sprinkler heads | |||||

Tube size |

| |||||||

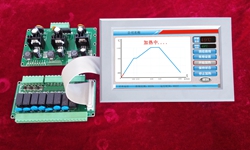

Control system |

| 1.NBD-101EP embedded operating system Chinese and English interchange graphical interface, 7 inch real color touch screen input, intelligent man-machine dialogue mode, real-time heating power display, non-linear pattern temperature correction; The experimental report is generated independently, and the experimental data is exported for unlimited times. | ||||||

Temp Accuracy | +/- 1 ℃ | |||||||

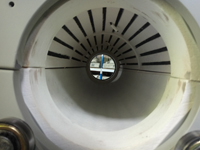

Heating chamber |

| Ring heating of Mo-doped Fe-Cr-Al alloy | ||||||

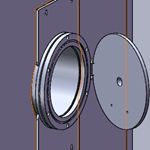

密封系统 |

|

| ||||||

真空度:≤10Pa(自配机械泵) | ||||||||

压力测量与监控 |

| 采用带有减震油的机械压力表,可以防止压力表指针损坏。 | ||||||

供气系统 |

| 采用浮子流量计控制气体流速,与设备集成为一体,且出厂前已进行漏气测试工作。 | ||||||

净重 | 180KG | 240KG | 300KG | |||||

1. 设备炉膛温度≥300℃时,禁止打开炉膛,避免受到伤害; 2. 设备使用时,若绝对压力表读数大于0.15MPa,以防止压力过大冲开密封法兰; 3. 设备建议处理高熔指纤维的聚丙烯,使用200h后将炉管旋转180℃; 4. 真空下使用时,设备使用温度不得超过<800℃。 | ||||||||

服务支持 | 1年质保,提供终身支持(保修范围内不包括易耗部件,例如炉管和密封圈等) | |||||||

免责声明:本站产品介绍内容(包括产品图片、产品描述、技术参数等),仅供参考。可能由于更新不及时,或许导致所述内容与实际情况存在一定的差异,请与本公司客服人员联系确认。本站提供的信息不构成任何要约或承诺,诺巴迪公司不定期完善和修改网站任何信息,恕不另行通知。

相关产品

Equipment introduction:

Anaerobic cleaning sintering furnace (vacuum calcining furnace, vacuum atmosphere cleaning furnace) is from the market demand and customer production pain point, this equipment can be used for anaerobic microhole cleaning of melt-blown cloth nozzle, the product can be applied to 300/450/600/800 nozzle 0.2~0.25mm microhole cleaning. Polypropylene for cleaning high-melt finger fibers in an anaerobic environment; Welcome friends to order. More specifications to provide manufacturers customized.

推荐产品

2-way float lengthening gas mixing tank

Large bell jar sintering furnace

well-type crucible melting furnace 0.1L 1200℃

Automatic hydrogen making machine H300

Vertical tube furnace 1500℃

Split pit furnace for glove box

Anaerobic well type sintering furnace (glove box + well type furnace)

Rotary microwave heating furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China