NOBODY tube furnace, box furnace type naming rules

Release time: 2020-04-16 08:50:20 Number of views: 5591

Equipment Introduction:

The mini tube furnace is an experimental device used for the heat treatment of various materials. It is mainly used in industries such as rare earth preparation, electronic lighting, crystal annealing, bioceramics, electronic ceramics, special alloys, magnetic materials, and precision casting. It is primarily applied in scenarios such as vacuum sintering, atmosphere-protected sintering, vacuum coating, CVD experiments, and material composition measurement.

Configuration details

| Equipment features: 1. Double-layer air-cooled structure; 2. High-purity Al2O3 fiber refractory insulation material, energy-saving and consumption reduction; 3. High-purity alumina coating can extend the service life of heating elements; 4. Alumina tube plugs can help you establish a perfect temperature gradient inside the tube. | ||||||

Product model | NBD-O1200-25TI-80 | NBD-O1200-50TI-80 | |||||

Electrical specifications | AC220V 1.2KW | ||||||

Reachable temperature | 1200 ℃ (<1小时) | ||||||

Long-term operating temperature range | 300~1150℃ | ||||||

eating rate | ≤ 20 ℃/分钟 | ||||||

Heating zone length | 200mm | ||||||

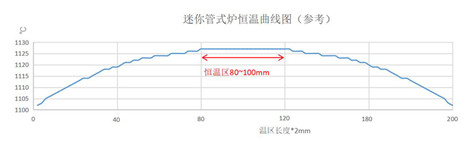

Constant temperature zone length | 120mm | ||||||

Furnace tube dimensions | Φ25*600mm | Φ50*600mm | |||||

Temperature field distribution |

| As shown in the figure: This is the temperature zone curve of the equipment (constant temperature zone size: 100mm) | |||||

Control system |

| 1. Can pre-store 15 temperature curves, avoiding the hassle of repeated settings for different experimental processes; 2. The experimental process is more intuitive, and operation is more convenient; 3. NBD-101E embedded operating system with bilingual (Chinese and English) graphical interface, 7-inch true color touch screen input, intelligent human-computer dialogue mode, nonlinear sample temperature correction; 4. Features over-temperature alarm, broken thermocouple prompt, leakage protection, etc. | |||||

Temperature accuracy | +/- 1 ℃ | ||||||

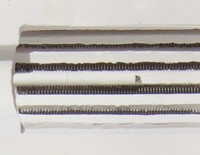

Heating element |

| Mo-doped Fe-Cr-Al alloy | |||||

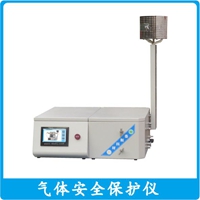

Sealed system |

|

|

| ||||

Vacuum degree:≤10Pa(Mechanical pump) | |||||||

Pressure measurement and monitoring |

| Using a mechanical pressure gauge, the case is airtight, effectively protecting the internal components from environmental influences and foreign matter intrusion, while also having strong corrosion and high-temperature resistance. | |||||

Net weight | 20KG | ||||||

Precautions for using the equipment | 1. When the furnace temperature of the equipment is ≥300°C, it is prohibited to open the furnace to avoid injury; 2. During equipment use, the pressure inside the furnace tube must not exceed 0.125MPa (absolute pressure) to prevent excessive pressure from damaging the equipment; 3. When using under vacuum, the equipment operating temperature must not exceed 800°C; 4. The internal pressure of the gas cylinder is relatively high. When introducing gas into the furnace tube, a pressure reducing valve must be installed on the cylinder. It is recommended to purchase a small pressure reducing valve for experimental use with a range of 0.01MPa-0.15MPa, which will be more precise and safe during use; 5. When the furnace body temperature exceeds 1000°C, the furnace tube must not be in a vacuum state. The pressure inside the furnace tube should be equivalent to atmospheric pressure, maintaining a normal pressure state; 6. The long-term operating temperature of high-purity quartz tubes is ≤1100°C; 7. During heating experiments, it is not recommended to close the exhaust valve and the inlet valve at the flange end of the furnace tube. If it is necessary to close the gas valve to heat the sample, the pressure gauge reading must be monitored at all times. If the absolute pressure gauge reading exceeds 0.15MPa, the exhaust valve must be immediately opened to prevent accidents (such as furnace tube rupture or flange flying out). | ||||||

| |||||||

Service Support | 1-year warranty, lifetime support provided (wearable parts such as furnace tubes and sealing rings are not included in the warranty) | ||||||

Disclaimer: The product introductions on this site (including product images, descriptions, and technical parameters) are for reference only. There may be discrepancies between the stated content and actual conditions due to untimely updates. Please contact our customer service personnel for confirmation. The information provided on this site does not constitute any offer or commitment. Nobody Company reserves the right to improve and modify any information on the website from time to time without prior notice.

Related products

|

|

推荐产品

推荐产品

Rotary pendulum oxidation furnace (silicon nitride tube)

Expansion coefficient tester

1200 ℃ CVD integrated machine

Heat resistant material test furnace

Large capacity muffle furnace 1700℃

Ultra high pressure and high temperature sintering furnace

Horizontal silent ball mill mixer

1.5C vacuum pump

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China