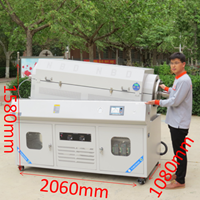

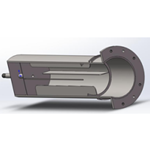

Industrial rotary pendulum sintering furnace

Release time: 2020-04-11 17:03:45 Number of views: 2525

Equipment introduction: Designers from the market demand and customer sintering process,This production vacuum atmosphere rotary furnace has been developed,This equipment can be used for lithium battery anode and cathode materials, rare earth materials, chemical catalysts, magnetic materials, metal powder hydrogen reduction and other aspects of material heat treatment production and preparation。Especially suitable for production enterprises, welcome new and old customers to send materials for test fire verification。

Configuration details

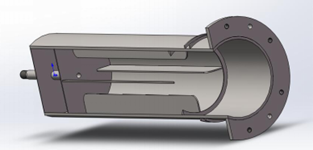

| 1.Material in the furnace tube constantly turning, heat evenly, fully contact with the reaction atmosphere, to ensure that the material full reaction; 2.High purity Al2O3 fiber refractory insulation material, excellent insulation effect, reduce the power consumption of equipment; 3.Advanced dynamic sealing device is adopted to ensure that the equipment can be used in vacuum and atmosphere; 4.Products use automatic control mode, equipped with 7 inch touch screen real-time tracking display device status; 5.The furnace body part can achieve -5-30° tilt, convenient for customers to discharge the material operation; | ||||||||||

Product model | NBD-RT1200-300T33 | ||||||||||

Electrical specification | AC380V 21KW | ||||||||||

Accessible temperature | 1200 ℃ (1 hour) | ||||||||||

Continuous temperature | 1100 ℃ (continuous) | ||||||||||

Heating rate | ≤ 20 ℃/minutes | ||||||||||

Length of heating zone | 900mm | ||||||||||

Tube size |

| ||||||||||

Control system |

| 1.Adopt automatic control mode, touch screen real-time display device data; 2.The experiment process is more intuitive and the operation is more convenient; 3.It has the functions of over temperature alarm, breaking even prompt, leakage protection and so on。 | |||||||||

Temperature accuracy | +/- 1 ℃ | ||||||||||

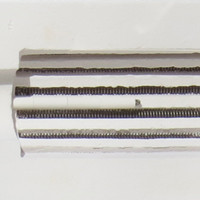

Heating element |

| Mo-doped Fe-Cr-Al alloy | |||||||||

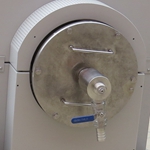

Sealing system |

|

|

| ||||||||

Vacuum degree:≤10Pa(Mechanical pump) | |||||||||||

Pressure measurement and monitoring |

| The mechanical pressure gauge with damping oil is used to produce damping when the pressure fluctuates and reduce the pointer to swing back and forth. | |||||||||

Air supply system |

| Float flowmeter is used to control the flow rate of gas, integrated with the equipment, and the leakage test has been carried out before leaving the factory. | |||||||||

Net weight | 800KG | ||||||||||

Precautions for device use | 1.Equipment furnace temperature ≥300℃,Do not open the furnace to avoid injury; 2.When the equipment is in use, the pressure inside the furnace shall not exceed 0.125MPa (absolute pressure),To prevent equipment damage caused by excessive pressure; 3.The equipment is recommended to handle micron powder or granular samples,Nano powder is not recommended to use this product; 4.When used under high vacuum (10 to the minus 3 Pa),The operating temperature of the equipment shall not exceed800℃。 | ||||||||||

Service support | 1 year warranty with lifetime support (The warranty does not include consumable parts, such as furnace tubes and sealing rings)。 | ||||||||||

Disclaimer: The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. Nobardi will improve and modify any information on this site from time to time without prior notice.

Related products

|

|

|

推荐产品

Vertical tube furnace 1500℃

Medium vacuum atmosphere pendulum rotary sintering furnace 1200℃

Sliding rail mobile fast annealing furnace

Manual button battery sealing machine

Large high temperature vacuum atmosphere muffle furnace

High temperature tube furnace 1500℃

RTP rapid steaming sintering furnace

Openable vertical tube furnace 1200℃

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China