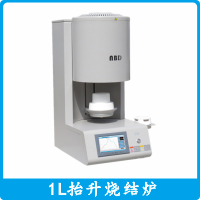

Jun porcelain sintering furnace

Release time: 2020-04-11 14:59:01 Number of views: 2358

Equipment introduction:

The equipment has a large enough sintering space, suitable for laboratory sintering research can also be used for industrial production。The products are mainly used in electronic components, art ceramics, structural ceramics, thick film circuit, magnetic materials, metal heat treatment and other industries。This product is on the basis of the box type electric furnace through the pipeline will be transported to the furnace to fill the whole furnace, so as to achieve the product in the atmosphere protection environment of high temperature sintering or heat treatment。

Configuration details

| 1. The double-layer air-cooled structure greatly reduces the surface temperature of the shell; 2. Equipped with high purity heating element with excellent acid and corrosion resistance; 3. Refractory thermal insulation materials manufactured by advanced technology have low heat loss and help to reduce the power of equipment; 4. Large sintering space, can be used for industrial production; 5. The top of the furnace is provided with an exhaust chimney to effectively eliminate the volatiles produced in the sintering process; 6. Touch screen operation, intuitive display temperature curve; | ||||||||

Product model | NBD-M1500-50TI | NBD-M1500-80TI | NBD-M1700-50TI | NBD-M1700-80TI | |||||

Electrical specification | AC380V 25KW | AC380V 50KW | AC380V 35KW | AC380V 80KW | |||||

Accessible temperature | 1500℃(<1hour) | 1700℃(<1hour) | |||||||

Continuous temperature | 1450℃(continuous) | 1650℃(continuous) | |||||||

Heating rate | ≤20℃/minutes | ||||||||

Furnace size | 500*500*800mm | 800*1000*1000mm | 500*500*800mm | 800*1000*1000mm | |||||

Control system | 1.Intelligent man-machine dialogue window, easy to operate, and direct real-time display of sintering data; 2.15 curves can be pre-stored, and each curve can be set with 30 "time-temperature" nodes, eliminating the process of modifying curves repeatedly; 3.It has the functions of over temperature alarm, breaking even prompt, leakage protection and so on。  |

| |||||||

Temperature accuracy | +/- 1℃ | ||||||||

Heating element |

|

| |||||||

Excellent acid and corrosion resistance of silicon carbon rod/silicon molybdenum rod heating element | |||||||||

Precautions for device use | 1.When the furnace temperature of the equipment is more than 300℃, it is forbidden to open the furnace to avoid injury; 2.The slight crack produced by continuous use of furnace is a normal phenomenon and does not affect the normal use of equipment; | ||||||||

Service support | 1 year warranty with lifetime support (consumable parts are not covered by warranty). | ||||||||

Disclaimer: The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. Nobardi will improve and modify any information on this site from time to time without prior notice。

Related products

推荐产品

MiNi tube furnace 1200℃

Lift type large capacity sintering furnace

High vacuum atmosphere muffle furnace

well-type crucible melting furnace 0.1L 1200℃

1200℃ box furnace (exhaust gas treatment equipment)

Open-sided industrial sintering furnace

Vertical tube Furnace (LT1700-80TI)

12L intelligent box furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China