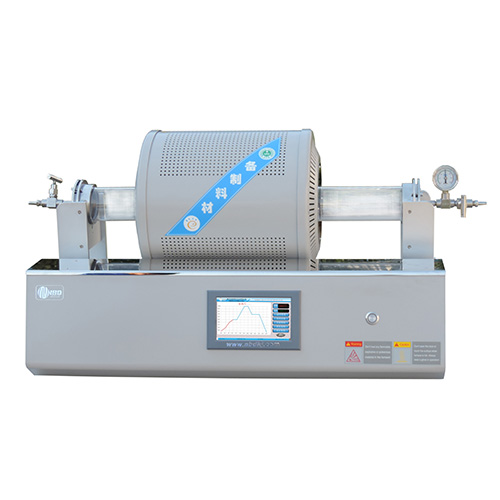

Double layer industrial sintering furnace

Release time: 2020-04-11 11:53:46 Number of views: 2312

Product characteristics:

1、The shell is made of high quality cold rolled steel plate, and the surface is treated with plastic spraying process. The furnace door adopts side door structure, which is flexible in closing and opening。

2、The closed furnace is made of spiral shape with electric thermal alloy wire as heating element,Coiled around the walls of the furnace,The furnace temperature extends the service life evenly during heat dissipation。3、This series of industrial furnace uses light alumina polycrystalline fiber insulation refractory material,The heat storage and thermal conductivity reduce the furnace heat storage heating time is shortened, the surface temperature is low, the empty furnace loss rate is small, and the power consumption is greatly reduced;

4、This series of industrial furnaces support non-standard customization。

Support non - standard customization, free contact number:400-000-3746

Disclaimer: The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. Nobardi will improve and modify any information on this site from time to time without prior notice.

推荐产品

Split vertical ingot melting furnace

Vertical homogenizing melting furnace

.png)

3-heating zone type tube furnace 1200℃

Three temperature zone 1700 ℃ tube furnace

Intelligent double temperature zone tube furnace 1500℃

Slide rail rapid annealing furnace

High temperature physical property test system

MINI muffle furnace ( drop down door)

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China