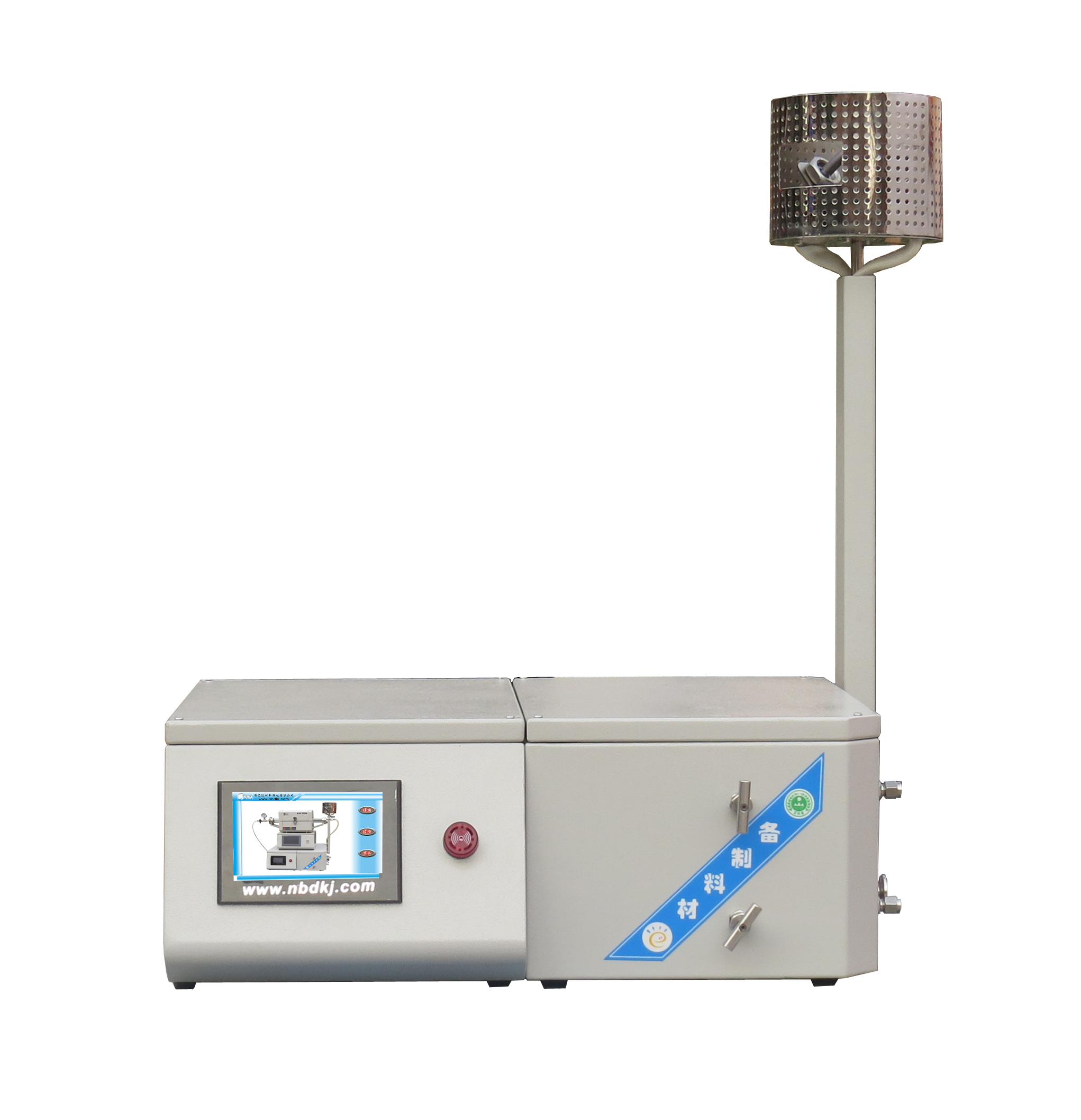

Vertical double tube sintering furnace

Release time: 2020-04-11 11:52:09 Number of views: 2060

Equipment introduction:

Mainly used in steel mills, special steel, mechanical processing, chemical machinery, heavy industry, metallurgical smelting, casting, forging, flange ring parts, pipe fittings, head, long shaft, steel components, wire drawing, environmental protection equipment, machinery supporting enterprises, loader, diesel engine, military and other industries of heat treatment workshop heating.

Equipment characteristics:

Double tube vertical annealing furnace is divided into high temperature furnace and medium temperature furnace. The highest operating temperature of high temperature furnace is within 1200℃, medium temperature furnace is within 950℃ and low temperature annealing furnace is within 650℃,According to the characteristics of the respective product selection, furnace size, load according to customer requirements.

Equipment introduction:

Mainly used in steel mills, special steel, mechanical processing, chemical machinery, heavy industry, metallurgical smelting, casting, forging, flange ring parts, pipe fittings, head, long shaft, steel components, wire drawing, environmental protection equipment, machinery supporting enterprises, loader, diesel engine, military and other industries of heat treatment workshop heating.

Equipment characteristics:

Double tube vertical annealing furnace is divided into high temperature furnace and medium temperature furnace. The highest operating temperature of high temperature furnace is within 1200℃, medium temperature furnace is within 950℃ and low temperature annealing furnace is within 650℃,According to the characteristics of the respective product selection, furnace size, load according to customer requirements.

This series of products can be customized, welcome to call to negotiate:400-000-3746.

Disclaimer: The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. Nobardi will improve and modify any information on this site from time to time without prior notice.

Equipment introduction:

Mainly used in steel mills, special steel, mechanical processing, chemical machinery, heavy industry, metallurgical smelting, casting, forging, flange ring parts, pipe fittings, head, long shaft, steel components, wire drawing, environmental protection equipment, machinery supporting enterprises, loader, diesel engine, military and other industries of heat treatment workshop heating.

Equipment characteristics:

Double tube vertical annealing furnace is divided into high temperature furnace and medium temperature furnace. The highest operating temperature of high temperature furnace is within 1200℃, medium temperature furnace is within 950℃ and low temperature annealing furnace is within 650℃,According to the characteristics of the respective product selection, furnace size, load according to customer requirements.

This series of products can be customized, welcome to call to negotiate:400-000-3746.

Disclaimer: The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. Nobardi will improve and modify any information on this site from time to time without prior notice.

推荐产品

Spiral heater

Constant pressure vacuum rotary pendulum sintering furnace

Vertical high-temperature tube furnace (Type 1)

Gas safety protection device for tube furnace

High magnetic induction quenching furnace

Medium denture waxing furnace

Large scale multi temperature zone vacuum tube furnace

Automatic hydrogen making machine H500

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China