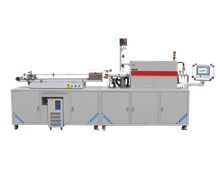

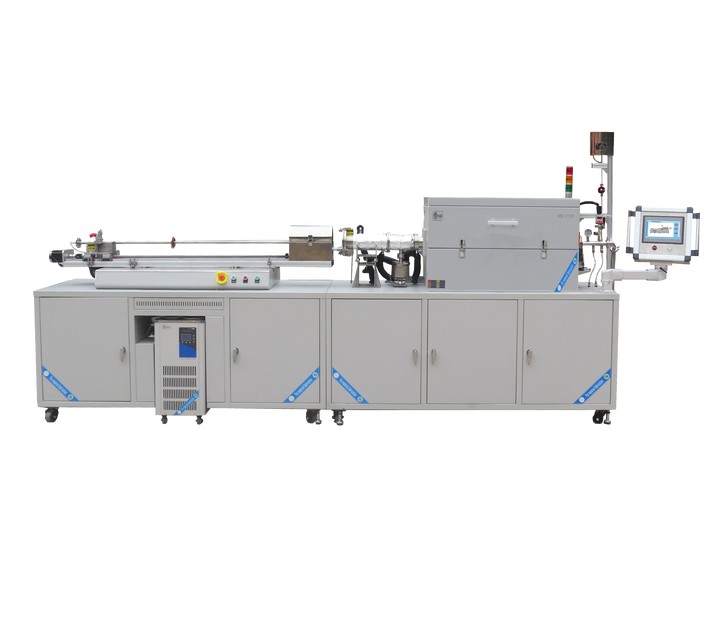

Automatic hydrogen reduction furnace Type II

Release time: 2020-04-10 23:36:34 Number of views: 5702

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

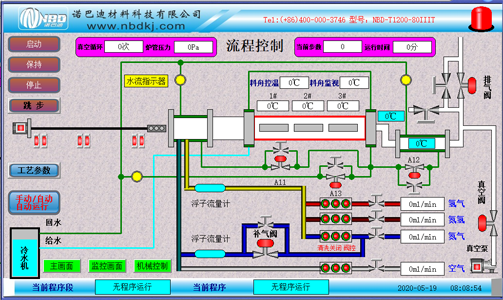

※ Model: NBD-T1200-80T33

※Temperature control accuracy: ±1℃

※ Touch screen size: 7 inches

※ Rated voltage: three-phase 380V

※ Rated power: 12KW

※ Sensor type: Type S thermocouple in furnace, type K thermocouple in load box

※ Accessible temperature: 1200℃

※ Rated temperature: 1150℃

※ Pipe diameter: Outer diameter Φ80× length 1445mm

※ Furnace body size: 4500×800×2100mm

※ Recommended heating rate: 10℃/min

※ Weight: About 850KG

Customer Service:

This series of products all support non-standard customization, welcome to call: 400-000-3746.

推荐产品

Vertical quenching furnace

Automatic feed and feed hydrogen absorption sintering furnace

Hydrogen reduction integrated sintering furnace (1500 ℃)

PECVD system

Large bell jar sintering furnace

Automatic hydrogen reduction furnace Type III

Vertical double tube sintering furnace

Mini Fluidised Bed Vertical Tube Furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China