PECVD Plasma Chemical Vapor Deposition System

Release time: 2020-04-10 23:09:09 Number of views: 2673

This product consists of a solid-state plasma source, a gas proton flow control system, a substrate temperature control system, and a vacuum system. It uses the Nobadi operating software with centralized bus control technology. Suitable for the deposition of SiO2 and SiNx thin films at room temperature to 1200 ℃, and can also achieve TEOS source deposition, SiC film layer deposition, and liquid gas source deposition of other materials. It is particularly suitable for the deposition of efficient protective layer films on organic materials and non-destructive passivation films at specific temperatures.

Configuration details

| 1. The cleaning and coating process is completed in one go, eliminating secondary contamination; 2. The top-opening structure facilitates sample observation; 3. The product adopts an automatic control system with a touch screen and digital display; 4. The equipment has a high degree of integration; 5. A stable RF power supply and uniform temperature distribution improve film quality; | |||||||||

Product model | NBD-PECVD1200-80TI | |||||||||

Electrical specifications | AC220V 4KW | |||||||||

Reachable Temperature | 1200 ℃ | |||||||||

Continuous temperature | 1150 ℃ | |||||||||

Heating rate achievable | ≤ 20 ℃/分钟 | |||||||||

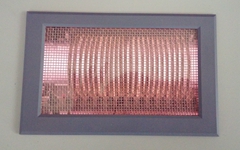

RF power supply | 500W 13.56MHz | |||||||||

Furnace tube size | Φ80*1200mm | |||||||||

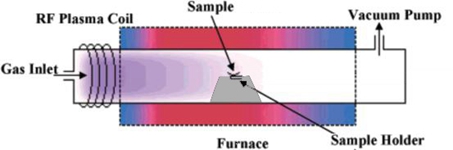

| Sedimentation diagram |

| As shown in the figure: This is a schematic diagram of the deposition process of the device. | ||||||||

Control system |

| 1. The NBD-101EP embedded operating system features a bilingual graphical interface for English and Chinese, a 7-inch true color touch screen input, an intelligent human-machine dialogue mode, real-time heating power display, and non-linear sample temperature correction; it can automatically generate experimental reports and export experimental data an unlimited number of times. 2. The experimental process is more intuitive, and the operation is more convenient; 3. It has functions such as over-temperature alarm, open-couple prompt, and leakage protection. | ||||||||

Temperature accuracy | +/- 1 ℃ | |||||||||

Heating element |

| Mo-doped Fe-Cr-Al alloy | ||||||||

Sealed system |

|

|

| |||||||

Vacuum degree: ≤10Pa (mechanical pump) | ||||||||||

Pressure measurement and monitoring |

| Using a digital vacuum gauge can make the equipment's vacuum level more intuitive and the experimental results more accurate. | ||||||||

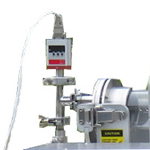

Gas supply system |

| Adopt two-way proton flow meters to precisely control the gas flow rate, integrated with the equipment. | ||||||||

Net weight | 360KG | |||||||||

Precautions for using the equipment | 1. When the equipment furnace temperature is ≥300°C, do not open the furnace to avoid injury; 2. During equipment use, the pressure inside the furnace tube must not exceed 0.125MPa (absolute pressure) to prevent excessive pressure from damaging the equipment; 3. When using under vacuum conditions, the operating temperature of the equipment must not exceed 800°C. 4. The internal gas pressure in the gas supply steel cylinder is relatively high. When introducing gas into the furnace tube, a pressure reducing valve must be installed on the cylinder. It is recommended to purchase a small pressure reducing valve for experimental use, with a range of 0.01MPa-0.15MPa, which will be more precise and safe during use. 5. When the furnace body temperature exceeds 1000°C, the furnace tube must not be in a vacuum state; the pressure inside the furnace tube should be equivalent to atmospheric pressure, maintaining a normal pressure state; 6. The long-term operating temperature of high-purity quartz tubes should be ≤1100°C 7. During heating experiments, it is not recommended to close the exhaust valve and inlet valve at the flange end of the furnace tube. If it is necessary to heat the sample with the gas valves closed, the pressure gauge reading must be monitored at all times. If the pressure gauge reading exceeds 0.02MPa, the exhaust valve must be opened immediately to prevent accidents (such as furnace tube rupture or flange flying out). | |||||||||

Service Support | 1-year warranty, lifetime support provided (warranty does not cover consumable parts such as furnace tubes and seals). | |||||||||

Disclaimer: The product introductions on this site (including product images, descriptions, and technical parameters) are for reference only. There may be discrepancies between the stated information and actual conditions due to untimely updates; please contact our customer service personnel for confirmation. The information provided on this site does not constitute any offer or commitment. Nobady Company reserves the right to improve and modify any information on the website periodically without prior notice.

推荐产品

Split vertical ingot melting furnace

High magnetic induction quenching furnace

Industrial annealing sintering furnace

2 station glove box

Multi-function high temperature pit furnace

Touch screen mass flow control distribution cabinet

Glove box plus high temperature furnace, etc

High temperature, high pressure automatic feeding tube furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China