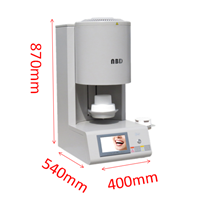

bottom-loading zirconia furnace

Release time: 2017-11-16 14:38:04 Number of views: 10769

Equipment introduction:

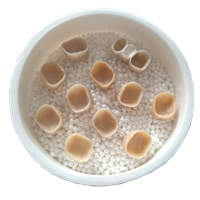

Self-cleaning denture sintering furnace is suitable for high temperature crystallization of zirconia ceramic materials. The high purity molybdenum disilicate special heating element and self-cleaning cavity can effectively prevent the denture sample from being contaminated by volatile matter. The heating element is distributed around and the furnace temperature is uniform to ensure the denture sintering effect is uniform.

Configuration

| 1. The heating element is distributed around the barrel, so that the temperature field is more uniform; | ||

Model | NBD-B1700-10TI | ||

Electrical Spec | AC220V 1.8KW | ||

1700℃ | |||

Max working temps. | 1650℃ | ||

heating rate | ≤20℃/min | ||

Chamber | Φ100*120mm | ||

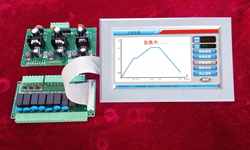

Control system |

| 1. 15 temperature curves can be pre-stored, and 30 sections of "temperature-time" axis can be set for each curve, avoiding the trouble caused by repeated setting of different experimental processes; | |

Temp Accuracy | +/- 1℃ | ||

heating element | Molybdenum disilicate special heating element | ||

Net weight | 60KG | ||

Cautions | If you want to sinter zirconium discs soaked with dye, be sure to dry them completely before placing them in the equipment for sintering to extend the service life of the equipment. | ||

Service | 1 year warranty with lifetime support (The warranty does not include consumable parts, such as furnace tubes and sealing rings). | ||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. Nobardi will improve and modify any information on this site from time to time without prior notice.

Related products

|

|

|

|

推荐产品

CMT furnace sliding rail tube furnace 1200℃

Roll to roll two-dimensional material preparation system

Small CVD system

Large caliber intelligent tube furnace 1200℃

Rotary pendulum oxidation furnace (silicon nitride tube)

Anticorrosive mini muffle furnace

Insulation mold pressure test system

Insulation sheet die

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China