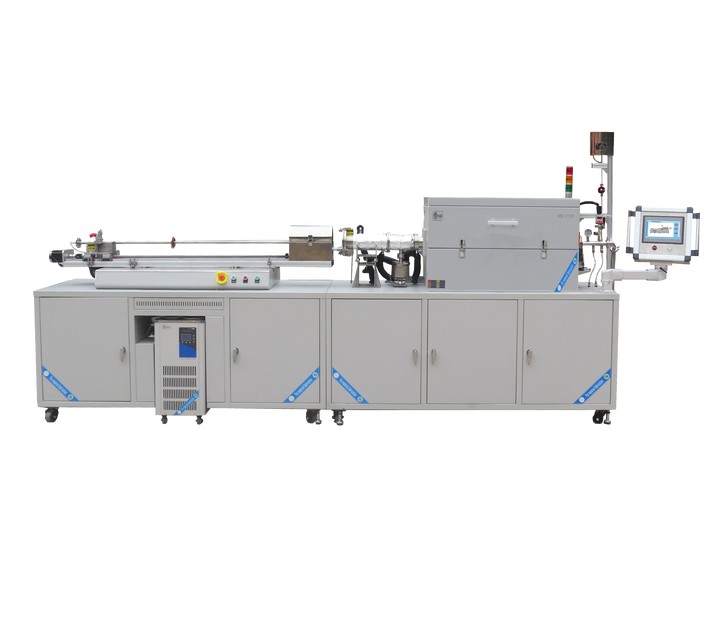

Zirconia denture batch sintering furnace

Release time: 2017-11-16 14:37:21 Number of views: 4680

Commercial use: Widely used zirconia denture batch pre-firing and sintering, the overall use of mature manufacturing process, from the point of view of aesthetic art, according to the ergonomic point of view to design. The furnace is made of high purity alumina lightweight fiber material with low thermal conductivity and bulk density. Compared with traditional heavy materials, the temperature uniformity of the equipment reflects the essential difference. The heating element adopts high purity silicon molybdenum rod, and the control interface adopts large touch screen, easy to operate. The control mathematical model adopts PID self-learning fuzzy control, so that the temperature control accuracy is kept at ±1℃. The lifting system adopts the linear guide design of stepless speed control. The zirconia denture batch sintering furnace runs smoothly, and the zirconia denture batch sintering furnace is convenient and reliable to load materials. The annular heater is placed so that the sample product you train has consistency.

Product specification: NBD-B1700-30IT

Product description: zirconia denture batch sintering furnace

Product features:

1. The heating element is annular distribution -- its temperature field is more uniform;

2. Electric lifting platform design, safe loading;

3. Vertical structure is more compact, reducing the occupation space;

4. Touch screen control system makes it easier to operate;

5. Stepless speed regulation, smooth running of linear guide rail;

6. Flexible sintering curve, 15 temperature curves can be preset;

7. 24 crucible can be placed at the same time, single sintering 480 single crown

Commercial use: Widely used zirconia denture batch pre-firing and sintering, the overall use of mature manufacturing process, from the point of view of aesthetic art, according to the ergonomic point of view to design. The furnace is made of high purity alumina lightweight fiber material with low thermal conductivity and bulk density. Compared with traditional heavy materials, the temperature uniformity of the equipment reflects the essential difference. The heating element adopts high purity silicon molybdenum rod, and the control interface adopts large touch screen, easy to operate. The control mathematical model adopts PID self-learning fuzzy control, so that the temperature control accuracy is kept at ±1℃. The lifting system adopts the linear guide design of stepless speed control. The zirconia denture batch sintering furnace runs smoothly, and the zirconia denture batch sintering furnace is convenient and reliable to load materials. The annular heater is placed so that the sample product you train has consistency.

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. Nobardi will improve and modify any information on this site from time to time without prior notice.

推荐产品

Vertical eight channel high-throughput tube furnace

Bottom-loading sintering furnace

High temperature blast drying oven

Three temperature zone PECVD system

Dual-channel K-type digital thermometer

Large high temperature vacuum atmosphere muffle furnace

Automatic hydrogen reduction furnace Type III

NBD-103(B) Vacuum system

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China

.png)