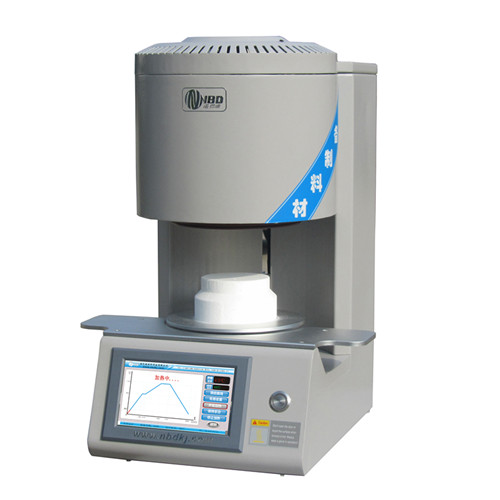

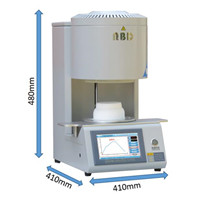

Bottom-loading high temperature sintering furnace

Release time: 2017-11-16 14:32:52 Number of views: 5172

Equipment introduction:

The design of the electric lifting platform greatly simplifies the loading step, the heating element is heated in a circular distribution, and the heating field is uniform, which is suitable for the heat treatment of metals, ceramics, glass and other materials. The lifting structure design can also be used for high temperature taking and discharging operation.

Configuration

| 1. Silent lifting platform design, ensure the stability of lifting, avoid material tilt, easy and fast loading; 3. Touch screen operation, intuitive display of temperature curve, make the operation more simple;

| ||||||||

Model | NBD-B1200-10TI | NBD-B1500-12TI | NBD-B1700-12TI | ||||||

Electrical Spec | AC220V 1.4KW | AC220V 1.5KW | AC220V 1.8KW | ||||||

Tmax | 1150℃ | 1450℃ | 1650℃ | ||||||

Heating rate | ≤20℃/分钟 | ||||||||

Chamber size | Φ90*70mm | Φ100*120mm | Φ100*120mm | ||||||

Control system |

| 1.NBD-101E embedded operating system Chinese and English interchangeable graphical interface, 7 inch true color touch screen input, intelligent man-machine dialogue mode, real-time heating power display, non-linear pattern temperature correction;

| |||||||

Temp Accuracy | +/- 1℃ | ||||||||

Heating element |

Molybdenum-doped Fe-cr-Al alloy heating wire | ||||||||

Net weight | 30KG | 55KG | 75KG | ||||||

Cautions | 1. When sintering the sample, the stove must be placed on the tray;

| ||||||||

Service | 1 year warranty with lifetime support (warranty does not cover consumable components such as furnace tubes and seals). | ||||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

|

|

|

|

推荐产品

CMT furnace sliding rail tube furnace 1200℃

Double temperature rapid annealing slide furnace

Intelligent tube furnace 1700℃

Mini well-type furnace

4C vacuum pump

Bottom-loading sintering furnace

CVDO1200-XTIG3Z

Insulation mold pressure test system

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China