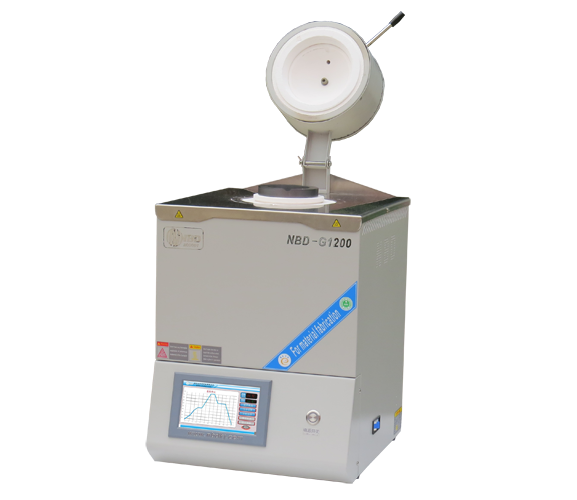

Microwave sintering furnace Microwave box type furnace

Release time: 2017-11-15 22:46:54 Number of views: 6096

Equipment introduction:

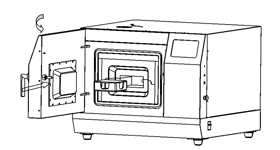

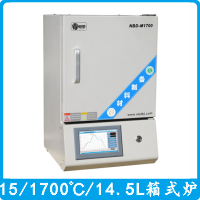

NBD-WBM-1700 microwave high temperature box furnace is a fine type, integrated furnace body, electrical control in a cabinet of microwave high temperature sintering equipment. Microwave sintering and high temperature microwave synthesis equipment up to 1600 degrees Celsius, widely used in the sintering of various materials or high temperature treatment of all kinds of inorganic materials under the air atmosphere synthesis, sintering, ashing, melting and heat treatment. The furnace is suitable for experimental research and development of new materials, and can achieve high quality and high efficiency firing of small batch products.

Configuration

| Technical features: | |||||

application area | 1. Inorganic powder synthesis | |||||

Model | NBD-WBM1700-12TI | NBD-WBM1700-15TI | ||||

Electrical Spec | AC220V/3KW | AC220V/3KW | ||||

Tmax | 1550℃ | |||||

output power | 0.2~1.4kW adjustable | |||||

Microwave output frequency | 2.45 GHz±25MHz | |||||

Microwave leakage rate | <2mW/cm² | |||||

type of cooling | water-cooling | forced air cooling | ||||

chamber size | L120*H40*D120 | L150*H153*D150 | ||||

Dimensions/Weight | 786*605*824 150KG | 786*605*824 150KG | ||||

Control system |

| NNBD-101P embedded operating system; | ||||

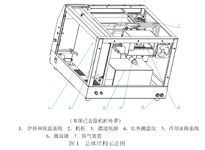

Structural summary |

| |||||

charging |

| |||||

Cautions | 1. The microwave source equipment works under high voltage and has high requirements for the working environment, so it should be avoided in places with large humidity and dust. | |||||

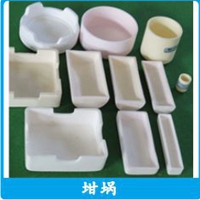

Service | 1 year warranty with lifetime support (warranty does not cover consumable parts such as saggar and seals). | |||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Configuration

| Technical features: | |||||

application area | 1. Inorganic powder synthesis | |||||

Model | NBD-WBM1700-12TI | NBD-WBM1700-15TI | ||||

Electrical Spec | AC220V/3KW | AC220V/3KW | ||||

Tmax | 1550℃ | |||||

output power | 0.2~1.4kW adjustable | |||||

Microwave output frequency | 2.45 GHz±25MHz | |||||

Microwave leakage rate | <2mW/cm² | |||||

type of cooling | water-cooling | forced air cooling | ||||

chamber size | L120*H40*D120 | L150*H153*D150 | ||||

Dimensions/Weight | 786*605*824 150KG | 786*605*824 150KG | ||||

Control system |

| NNBD-101P embedded operating system; | ||||

Structural summary |

| |||||

charging |

| |||||

Cautions | 1. The microwave source equipment works under high voltage and has high requirements for the working environment, so it should be avoided in places with large humidity and dust. | |||||

Service | 1 year warranty with lifetime support (warranty does not cover consumable parts such as saggar and seals). | |||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

推荐产品

glass tempering furnace

Horizontal vacuum atmosphere furnace

PECVD Plasma Chemical Vapor Deposition System

0.45L melting furnace 1200℃

Meltblowout cloth nozzle anaerobic cleaning furnace 1200℃

Production vacuum atmosphere pendulum rotary sintering furnace 1200℃

In situ observation of molten salt electroplating furnace

Vertical homogenizing melting furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China