High pressure hydrogen preheating and blowing system

Release time: 2025-08-08 19:29:55 Number of views: 2

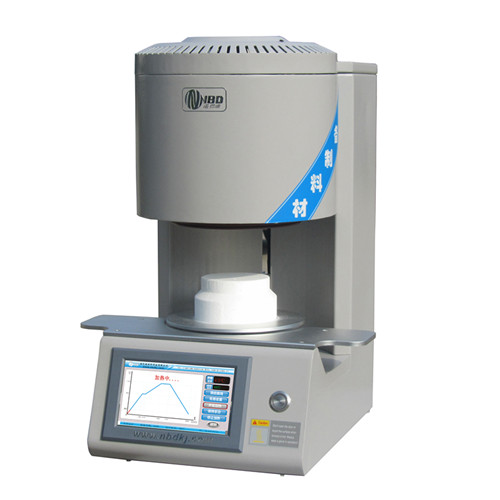

The high-pressure hydrogen preheating and blowing system is specifically designed for processes that require gas heating and pressure treatment in high temperature and high pressure environments. The system preheats hydrogen through resistance wire heating tubes and uses efficient insulation materials to minimize heat loss, thereby achieving efficient and uniform gas preheating and blowing. The gas pipeline in the system is made of 310S stainless steel material to ensure its stability and durability under high temperature conditions.

| Main features and advantages

| |

Equipment name | High pressure hydrogen preheating and blowing system | |

power supply | AC 220V 50HZ | |

rated power | 3.2KW | |

heating element | 310S light rod heater with a diameter of 15.8 * 319mm | |

sensor type | K-type thermocouple with a diameter of 1 * 600mm | |

Tmax | 1000℃ | |

Recommended heating rate | ≤5℃/min | |

Mass Flow Controller | S500 5SLM φ 6.35 double card sleeve 2-meter short wire fluorine rubber seal nitrogen calibration | |

Import and export of gas | Φ 10 double card sleeve connector | |

Overall dimensions of furnace body (without furnace frame) | 长550*高700*深565mm (炉架尺寸长600*高700*深600mm) | |

control system |

| 1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set;

|

Temperature Accuracy | +/- 1℃ | |

net weight | About 50KG | |

Service Support | One year limited warranty, providing lifetime support (the warranty does not include consumable parts such as processing tubes and O-rings, please order replacement parts at the relevant product below) | |

推荐产品

medium frequency induction melting furnace

Automatic feed and feed hydrogen absorption sintering furnace

Bottom-loading high temperature sintering furnace

3D printing vacuum furnace

1.5C vacuum pump

vacuum oven

Vertical homogenizing melting furnace

Split pit furnace for glove box

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China