1200 ℃ Rotating Swing CVD Coating Heating Furnace

Release time: 2025-07-22 19:49:41 Number of views: 63

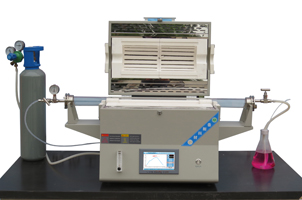

The 1200 ℃ rotating pendulum automatic feeding and discharging CVD (chemical vapor deposition) coating heating furnace is a highly integrated advanced equipment designed specifically for high-quality material surface coating under strictly controlled conditions. This device not only has high-temperature processing capabilities, but also combines rotation, oscillation, and automatic feeding and discharging functions to ensure uniform and efficient coating, making it suitable for multiple fields such as new material development, semiconductor manufacturing, and optical device preparation.

| main features

| ||

Equipment name | 1200 ℃ Rotating Swing CVD Coating Heating Furnace | ||

Specification and model | NBD-RT1200-100T2DF2LN | ||

power supply | AC380V 50HZ | ||

rated power | 4.5KW | ||

Number of temperature zones | Single temperature dual control | ||

precision | ±1℃ | ||

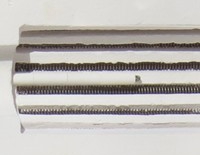

heating element | Alloy resistance wire | ||

sensor type | K-type thermocouple with a diameter of 2 * 420mm | ||

Tmax | 1200℃ | ||

Long term working temperature | 1100℃ | ||

heating rate | 1℃/H-20℃/Min | ||

Size of furnace temperature zone | Φ150*440(220+220)mm | ||

Tilt angle of furnace body | -5-20° | ||

Furnace tube specifications | 60*3*1000 middle 100*3*355/380, with 3 internal 20*3*340 scraper blades | ||

Furnace tube rotation speed | 1-10rpm | ||

feeding speed | 1-25ml/min (powder material) | ||

Maximum feeding particle size | <φ0.1mm | ||

Capacity of inlet and outlet tanks | 2L | ||

rotameter | 0.1-0.8L/min | ||

Furnace body size | Length 1763 * Height 1683 * Depth 795mm | ||

Furnace weight | 约272KG | ||

control system | |

1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set; 2. Pre order sintering is available to achieve unmanned sintering process curve sintering; 3. Real time display of sintering power, voltage and other information, recording of sintering data, and the ability to export for paperless recording; 4. Capable of remote control and real-time observation of equipment status; 5. Temperature correction: The difference between the main control temperature and the sample temperature is nonlinearly corrected throughout the sintering process.

| |

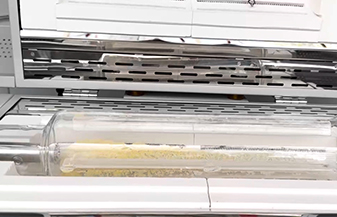

Furnace details |   | Variable diameter quartz tube with lifting plate | |

Weak pressure measurement and monitoring

|   | The whole body is made of 316L material, which can be preheated for various gases and corrosive gases to meet special process requirements, with a maximum temperature of 600 ℃. | |

heating element |   | Alloy resistance wire | |

Pressure measurement and monitoring |   | Adopting a mechanical pressure gauge, the gauge housing is of an airtight structure, which can effectively protect the internal components from environmental influences and debris intrusion, while also having strong corrosion and high temperature resistance capabilities | |

Gas supply system |   | The gas flow rate is controlled by a float flowmeter, which is integrated with the equipment and has undergone leak testing before leaving the factory. | |

Service and Support | One year limited warranty with lifetime support (warranty does not include consumable parts such as processing tubes and O-rings, please order replacement parts at the relevant product below). | ||

application area

Semiconductor industry: used for preparing surface coatings of high-purity silicon wafers, gallium nitride and other semiconductor materials.

New energy: providing high-performance coatings for lithium-ion battery electrode materials, fuel cell catalyst carriers, etc.

Optical components: Prepare anti reflective coatings, anti reflective films, etc. to enhance the performance of optical components.

Aerospace: Used for manufacturing key components such as high temperature resistant and wear-resistant aircraft engine blades and turbine discs.

Research experiment: Conduct new material development and performance testing in the laboratory to explore new coating technologies.

推荐产品

NBD-103(B) Vacuum system

Mini vacuum furnace for glove box

Homogeneous diffusion furnace

3C vacuum pump

Single temperature zone tube furnace 1200℃

Vertical tube furnace (saturated steam)

Extended tube furnace with single temperature zone 1500℃

High temperature vertical rapid pyrolysis furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China