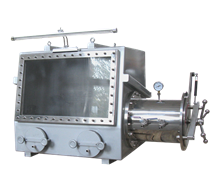

1200℃ box furnace (exhaust gas treatment equipment)

Release time: 2025-07-22 01:12:45 Number of views: 59

This equipment is designed for addressing the pollutants such as toxic and harmful substances, tar, and lipids generated during the sintering process of certain raw materials, as well as the exhaust congestion caused by the condensation of these substances when they encounter cold air at the normal chimney. An innovative tail gas treatment device has been designed. This box-type furnace device solves these problems through a series of special designs and ensures effective treatment and emission of tail gas.

|

main features

|

||

|

Equipment name |

Box furnace (with secondary combustion chamber) |

||

|

Specification and model |

NBD-M1200-40TI (B) + exhaust gas treatment equipment |

||

|

power supply |

380V 50HZ |

||

|

rated power |

12KW |

||

|

Number of temperature zones |

Single temperature and single control |

||

|

precision |

±1℃ |

||

|

heating element |

Alloy heating wire |

||

|

Type of sensor |

K-type thermocouple φ 1 * 250mm |

||

|

Tmax |

1200℃ |

||

|

Long-term operating temperature |

1150℃ |

||

|

heating rate |

1℃/H-20℃/Min |

||

|

Furnace temperature zone size |

Box-type furnace: length 400 * height 400 * depth 400mm

|

||

|

Float flow meter |

0.5-5L/min |

||

|

Range of digital differential pressure gauge |

-30-30Pa |

||

|

Furnace body size |

L 953 * H 1550 * D 855mm |

||

|

Weight of furnace body |

Approximately 260KG |

||

|

control system |

|

1. Sintering process curve setting: the setting curve is displayed dynamically, multiple process curves can be pre-stored for equipment sintering, and each process curve can be set freely;

|

|

|

FURNACE DETAILS |

|

||

|

Precautions for equipment use |

When the equipment hearth temperature is ≥ 300 ℃, do not open the reaction chamber to avoid injury;

|

||

|

Service and Support |

Year warranty and lifetime support (excluding consumable parts). | ||

推荐产品

TGB-2 Vacuum glove box

12L intelligent box furnace

Quick mounting flange

Sliding rail mobile fast annealing furnace

Manual button battery sealing machine

Thermogravimetric analysis (TGA) and condensation collection systems

CVD system T1500-XTID3Z

Rotary tube sintering furnace (Tmax1700℃)

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China