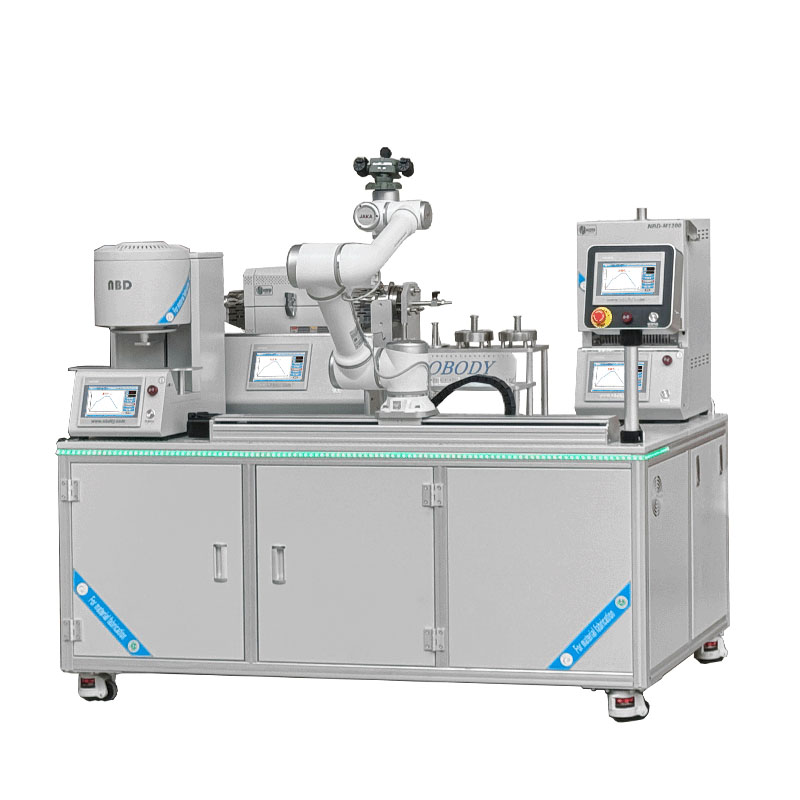

Intelligent Sintering Furnace AISF System (Automatic Intelligent Sintering Furnace)

Release time: 2025-07-04 17:44:30 Number of views: 74

Traditional sintering faces challenges such as long formula screening time and high risk of high-risk material operations, but the Zhiyao Tianshu AISF system has broken through! It is equipped with AI intelligent algorithms and high-precision automated robotic arms, which can complete massive material formula screening in a short period of time, greatly shortening the research and development cycle. For the sintering of toxic, harmful, and radioactive substances, this system achieves unmanned full process operation, eliminating personnel safety hazards from the source. With intelligent temperature control and dynamic monitoring technology, ensure stable and reliable sintering quality. The AISF system of Zhiyao Tianzhu, empowered by technology, opens up a new era of efficient, safe, and intelligent sintering!

| Equipment features:

| ||

Equipment name | Zhiyao Tianshu AISF system (fully automatic intelligent sintering furnace) | ||

Specification and model | Zhiyao Tianzhu AISF | ||

power supply | 220V 50HZ | ||

rated power | 6.95KW(2.5KW+1.2KW+2.5KW+0.4KW+0.35KW) | ||

Equipment name | electrical machinery | ||

Specification and model | MS1H4-40B30CB-T331R | ||

power supply | 220V 50HZ | ||

rated power | 400W | ||

trip | 900mm | ||

Equipment name | Collaborative robot | ||

Specification and model | JAKA C5/5kg | ||

power supply | 220V 50HZ | ||

rated power | 350W | ||

working radius | 954mm | ||

Maximum Load | 5Kg | ||

Number of joints | 6 of them | ||

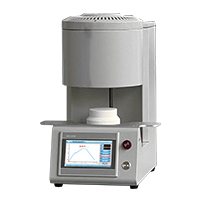

Equipment name |

| Electric furnace door box furnace | |

Equipment model | NBD-M1200-15TI | ||

Furnace space | 150 * 150 * 180mm (length*height*depth) | ||

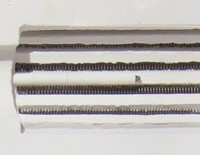

heating element |   | Resistance wire (Mo doped Fe-Cr-A1 alloy) | |

External dimensions | 340*610*420mm(长*高*深) | ||

Furnace door opening mode | Electric downward opening door | ||

Tmax | 1200℃ | ||

Continuous operating temperature | 1150℃ | ||

Electrical specifications | AC220V、3KW | ||

heating rate | ≤20℃/min | ||

Recommended heating rate | 10℃/min | ||

precision | ±1℃ | ||

Temperature measuring element | K type thermocouple | ||

Equipment name |

| Lift furnace | |

Equipment model | NBD-B1200-10TI | ||

Electrical specifications | AC220V 1.4KW | ||

Reachable temperature | 1200℃ | ||

Achievable heating rate | ≤20℃/min | ||

Temperature Accuracy | ±1℃ | ||

heating element |

| Fe Cr Al alloy doped with Mo for spiral heater | |

net weight | 30kg | ||

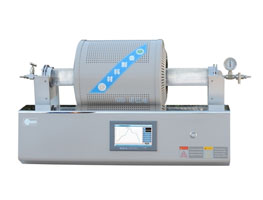

Equipment name |

| Mini tube furnace 1200 ℃ | |

Furnace tube size | Φ50*600mm | ||

Electrical specifications | AC220V 1.2KW | ||

Reachable temperature | 1200℃ | ||

Long term use temperature range | 300~1150℃ | ||

heating rate | 1℃/H-20℃/Min | ||

Heating zone length | 200mm | ||

Length of constant temperature zone | 120mmm | ||

control system | | 15 temperature curves can be pre stored to avoid the trouble caused by repeated settings of different experimental processes;

| |

Service and Support | 1-year warranty with lifetime support (warranty does not include consumable parts such as furnace tubes and seals). | ||

推荐产品

Vertical tube Furnace (LT1700-80TI)

1200 ℃ CVD integrated machine

CMT furnace sliding rail tube furnace 1200℃

Hydrogen reduction furnace

Medium frequency induction alloy sublimation furnace

Six temperature zone tube furnace (corrosion-resistant silicon carbide furnace tube)

Liquid-gas CVD all-in-one machine

Thermal Shrinkage and Expansion Tester

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China