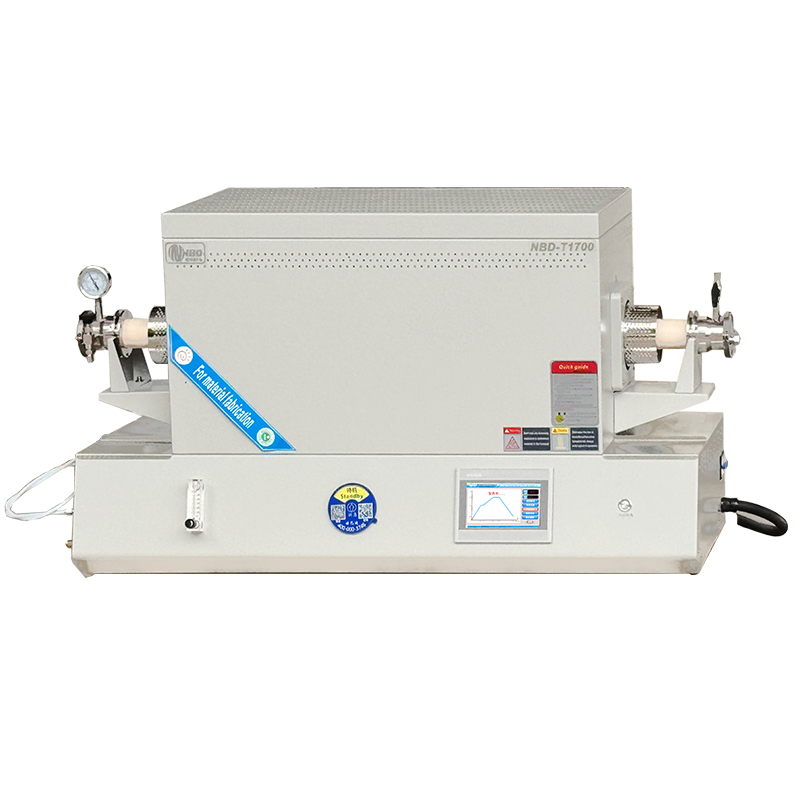

Three temperature zone 1700 ℃ tube furnace

Release time: 2025-06-04 22:31:43 Number of views: 145

The 1700 ℃ tube furnace with three temperature zones from Nobadi is a high-performance equipment designed specifically for high-temperature experiments and production. This device adopts advanced heating technology and intelligent control system, which can achieve precise temperature control in three independent temperature zones, with a temperature of up to 1700 ℃. Suitable for research and production needs in multiple fields such as materials science, chemical engineering, electronic semiconductors, etc.

| main features

| ||

Equipment name | Three temperature zone tube furnace | ||

Specification and model | NBD-T1700-60TP3F | ||

power supply | three-phase380V 50HZ | ||

rated power | 8KW | ||

Number of temperature zones | Three temperature and three control | ||

precision | ±1℃ | ||

Sensor type | B-type thermocoupleφ8*205mm | ||

Tmax | 1700℃ | ||

rated temperature | 1650℃ | ||

Recommended heating rate | ≤10℃/min | ||

Size of furnace temperature zone | Length (150+230+150) * Height 140 * Depth 160mm | ||

Furnace tube specifications | corundum tubeφ60*1300mm | ||

rotameter | 50-500ml/min | ||

Furnace body size | 1410mm in length, 740mm in height, and 560mm in depth | ||

Furnace weight | 约210KG | ||

control system |

| 1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set;

| |

| heating element

|

| High purity silicon molybdenum rod

| |

| Pressure measurement and monitoring

|

| Mechanical pressure gauges are used, and the gauge housing is of an airtight structure, which can effectively protect the internal components from environmental influences and debris intrusion. At the same time, it has strong corrosion resistance and high temperature resistance.

| |

Gas supply system |   | The gas flow rate is controlled by a float flowmeter, which is integrated with the equipment and has undergone leak testing before leaving the factory. | |

Weakly corrosive gas preheater

|   | The whole body is made of 316L material, which can be preheated for various gases and corrosive gases to meet special process requirements, with a maximum temperature of 600 ℃. | |

Equipment usage precautions

| When using the equipment, the absolute pressure gauge reading should not exceed 0.15MPa to prevent equipment damage caused by excessive pressure; | ||

Service and Support | 1-year warranty with lifetime support (warranty does not include consumable parts such as furnace tubes and seals). | ||

推荐产品

High temperature vertical quenching furnace

Rotary microwave heating furnace

Blast drying oven (galvanized)

Split vertical ingot melting furnace

Vertical double tube sintering furnace

Vacuum storage cabinet

Manual tablet press

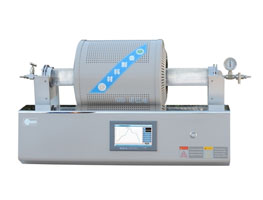

CMT furnace sliding rail tube furnace 1200℃

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China