1500 ℃ (80L) ultra large capacity box furnace

Release time: 2025-05-12 17:59:30 Number of views: 138

The 1500℃ (80L) ultra large capacity box furnace muffle furnace is a high-performance high-temperature heating equipment designed for material processing, experimental research, and production process development under high temperature conditions in laboratories and industrial applications. This muffle furnace is known for its large capacity (80 liters) and a working temperature range of up to 1500 degrees Celsius, making it suitable for a variety of complex process requirements.

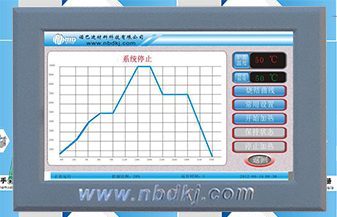

| main features 1. Working temperature The temperature can reach 1500℃, and high-purity silicon carbon rods are preferred as heating elements to ensure stable operation of the equipment in extreme high temperature environments. Rapid heating and insulation performance: The optimized heating system can achieve rapid heating and maintain a stable high temperature state, meeting the needs of long-term experiments or production. 80L Extra Large Capacity: Provides ample internal space, suitable for large-scale sample processing or heat treatment of large samples. Multi layer shelving structure: The shelving position can be adjusted according to needs, and the sample layout can be flexibly arranged to improve space utilization. 3. Precise temperature control PID intelligent temperature control system: adopting advanced PID controller to ensure temperature control accuracy of ± 1 ° C, meeting temperature sensitive process requirements. Real time monitoring: Equipped with high-precision temperature sensors, it can monitor temperature changes inside the furnace in real time to ensure consistency of process conditions. 4. Safety and Maintenance Over temperature protection: Built in over temperature protection device, automatically cuts off power when the temperature rises abnormally, preventing equipment damage. Emergency stop button: Set up a clear emergency stop button to ensure the safety of operators. Regular maintenance reminder: The system can set regular maintenance reminders to help users perform equipment maintenance in a timely manner and extend its service life. 5. Humanized design Double layer insulation structure: The outer layer is made of high-efficiency insulation materials to reduce heat loss, lower the shell temperature, and ensure safe operation. Convenient operating interface: touch screen or computer interface, making it easy for users to input parameters, start tests, and view results. Easy to clean: The internal design is simple, easy to clean and maintain, reducing downtime.

| ||

Equipment model | NBD-M1500-40TI | ||

power supply | AC380V/50HZ | ||

rated power | 15KW | ||

sensor type | S-type thermocouple | ||

Tmax | 1500℃ | ||

rated temperature | 1450℃ | ||

heating rate | 1℃/H-20℃/Min | ||

Furnace space | L440*H400*W500mm | ||

precision | ±1℃ | ||

Equipment external dimensions | L856*H1800*W1030mm | ||

Equipment weight | 约240KG | ||

control system |

| 1. 15 temperature curves can be pre stored to avoid the trouble caused by repeated settings of different experimental processes;

| |

heating element |

| High purity silicon carbide rod | |

Weakly corrosive gas preheater

|   | The whole body is made of 316L material, which can be preheated for various gases and corrosive gases to meet special process requirements, with a maximum temperature of 600 ℃. | |

Equipment usage precautions | 1.When the furnace temperature of the equipment is ≥ 300 ℃, it is forbidden to open the furnace to avoid injury; 2. Minor cracks caused by continuous use of the furnace are a normal phenomenon and do not affect the normal use of the equipment; | ||

| Service Support | 1-year warranty, providing lifetime support (excluding consumable parts within the warranty scope). | ||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to delayed updates, there may be some discrepancies between the content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment. Nuobadi Company may periodically improve and modify any information on the website without prior notice.

推荐产品

Zirconia denture batch sintering furnace

Carbon fiber annealing furnace

Desktop type Glove box

Five temperature zone square tube sintering furnace

Cold wall intermediate frequency induction melting furnace

Experimental apparatus for reducing and extracting alloy preparation

Open-sided industrial sintering furnace

25 station vacuum atmosphere tube furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China