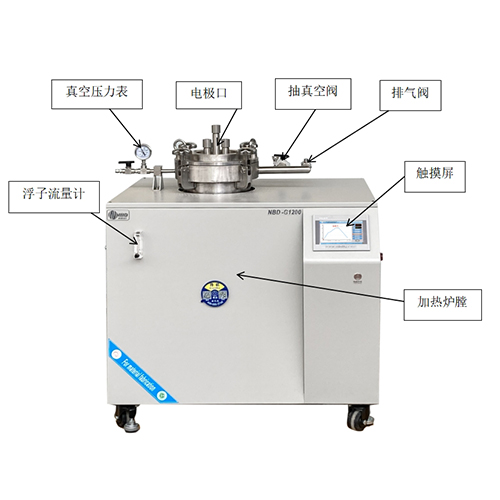

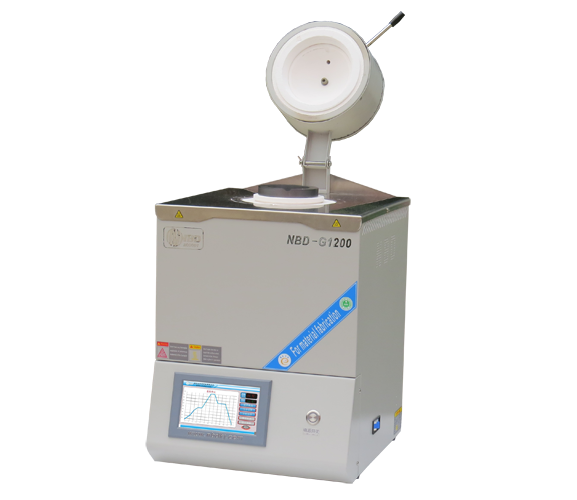

Vacuum molten salt electrolysis furnace

Release time: 2025-04-28 22:45:04 Number of views: 159

The vacuum molten salt electrolysis furnace is mainly used in the field of molten salt electrochemistry. High temperature molten salt, as an ion conductor, has a wide electrochemical window and fast reaction kinetics at high temperatures, making it an ideal electrolyte for electrochemical metallurgy. The electrolytic aluminum industry is a successful example of this. Based on this, we have developed a laboratory grade molten salt electroplating furnace to fill the market gap.

|

Equipment features:

| ||

Equipment name | Vacuum molten salt electrolysis furnace | ||

Specification and model | NBD-G1200-270TIFRD30L | ||

power supply | 三相380V 50HZ | ||

precision | ±1℃ | ||

rated power | 16KW | ||

Type of temperature measuring element | K type thermocouple,Φ2*420mm | ||

Heating method | Bottom heating+circular heating around | ||

Tmax | 1200℃ | ||

rated temperature | 1150℃ | ||

Rated voltage of electrolytic power supply | 15V | ||

Rated current of electrolytic power supply | 100A | ||

Draw true blank size | KF25 | ||

Air inlet size | Φ6.35 | ||

Exhaust port size | Φ 25mm pagoda joint | ||

Ultimate vacuum | 5-10pa (if higher vacuum degree is required, molecular pump can be selected) | ||

rotameter | 60-600ml/min | ||

Heating temperature zone size | Φ350*420mm | ||

Furnace body size | 995mm in length, 1200mm in height, and 910mm in depth | ||

Recommended heating rate | ≤5℃/min | ||

weight | 约380KG | ||

control system |

|

1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set; 2. Pre order sintering is available to achieve unmanned sintering process curve sintering; 3. Real time display of sintering power, voltage and other information, recording of sintering data, and the ability to export for paperless recording; 4. Capable of remote control and real-time observation of equipment status; 5. Temperature correction: The difference between the main control temperature and the sample temperature is nonlinearly corrected throughout the sintering process.

| |

heating element |

| Mo doped Fe Cr Al alloy | |

Vacuum material tank |   | reaction kettle | |

Batch delivery on-site |   | ||

Equipment usage precautions | 1. Minor cracks caused by continuous use of the furnace are a normal phenomenon and do not affect the normal use of the equipment; | ||

Service Support | 1-year warranty with lifetime support (warranty does not include consumable parts such as furnace tubes and seals). | ||

推荐产品

Φ95×50mm corundum crucible

Oscillating ball mill mixer

air blast drying oven

Chemical vapor deposition CVD all-in-one machine

1.5C vacuum pump

High temperature, high pressure automatic feeding tube furnace

0.45L melting furnace 1200℃

Anaerobic well type sintering furnace (glove box + well type furnace)

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China