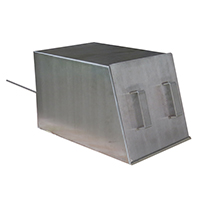

Split type five sided heating box furnace

Release time: 2025-04-06 21:37:00 Number of views: 166

1200℃ split-type five-sided heating box furnace is a specially designed device for high-temperature processing experiments, particularly suitable for material synthesis and heat treatment operations that need to be performed under inert atmospheres or vacuum conditions. The unique features of this muffle furnace lie in its split-type design and five-sided heating function, which not only provide uniform heating effects but also offer flexibility by enabling easy integration with glove boxes, ensuring safety and an oxygen-free environment during the experimental process.

| Main Features 1. Split Design Flexible installation: The split design allows the heating section to be installed separately from the control section, making it adaptable to different laboratory layouts and space constraints. Easy integration: This design is especially suitable for use in conjunction with gloveboxes, enabling the heating chamber to be conveniently placed inside the glovebox while the controller is located externally, saving space and enhancing operational safety. 2. Five-sided Heating System Uniform heating: The five-sided heating (bottom and four walls) design ensures uniform heating of samples throughout the process, reducing the impact of temperature gradients on experimental results. Rapid heating: Advanced heating elements and optimized heating structures enable the equipment to achieve rapid heating, improving work efficiency. 3. Precise Temperature Control PID intelligent temperature control system: Equipped with advanced PID controllers to ensure temperature control accuracy within ±1°C, meeting requirements for temperature-sensitive processes. Real-time monitoring: Built-in high-precision temperature sensors monitor changes in furnace temperature in real time, ensuring consistency in process conditions. 4. Various Atmosphere Environments Supports operation in inert gases (such as nitrogen, argon) and reductive gases (such as hydrogen), preventing sample oxidation or other chemical reactions. 5. Compatible with Gloveboxes Sealed design: The heating chamber uses high-quality sealing materials and technologies to ensure airtightness within the glovebox, preventing external air from entering. Interface compatibility: The equipment is equipped with standard interfaces for seamless integration with common gloveboxes, ensuring stable system operation. 6. Safety and Maintenance Over-temperature protection: Built-in over-temperature protection devices automatically cut off power when abnormal temperature increases occur, preventing equipment damage. Emergency stop button: A clearly marked emergency stop button is provided to ensure operator safety. Regular maintenance reminders: The system can be set to provide regular maintenance reminders, helping users perform timely equipment maintenance to extend its lifespan.

| ||

| Device Name | Split box furnace | ||

Specification model |

NBD-M1200-40(B)TIN | ||

power supply | 三相,380V,50Hz | ||

rated power | 10KW | ||

Number of temperature zones | Single temperature and single control (five sided heating) | ||

precision | ±1℃ | ||

sensor type | K-type thermocouple with a diameter of 2 * 600mm | ||

heating element | Alloy resistance wire | ||

Tmax | 1200℃ | ||

rated temperature | 1150℃ | ||

Recommended heating rate | ≤10℃/min | ||

Furnace space | Length 400 * Height 400 * Depth 400mm | ||

Size of silicon carbide for shed board | Length 390 * Height 10 * Depth 390mm | ||

Closed state furnace body size | Length 753 * Height 792 * Depth 870mm | ||

Open state furnace body size | 1320mm in length, 792mm in height, and 900mm in depth | ||

Control cabinet size | Length 478 * Height 228 * Depth 510mm | ||

total weight | Approximately 286KG (with control cabinet) | ||

control system | | 1. Sintering process curve setting: dynamic display of the set curve, the equipment can pre-store multiple process curves, and each process curve can be set freely; 2.reservation sintering is available to achieve unattended operation of the sintering process curve; 3. Real-time display of sintering power, voltage and other information, recording of sintering data, and export capability for paperless recording; 4. Remote control is available with real-time monitoring of equipment status; 5. Temperature correction: the difference between the main control temperature and the sample temperature is corrected non-linearly throughout the sintering process.

| |

heating element |   | Mo doped Fe Cr Al alloy

| |

Atmosphere protection box (optional) |

| The atmosphere protection box is an accessory device used inside a heating furnace, designed to create and maintain a specific atmospheric environment to protect the heated material from oxidation, contamination, or adverse reactions with other components in the air (customizable size).

| |

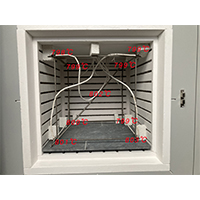

Temperature zone test |   | The temperature uniformity should ensure that under the set working temperature, the temperature difference at various points inside the furnace is as small as possible to guarantee that the samples placed inside are heated uniformly during heat treatment, thereby achieving consistent heat treatment results. To ensure the equipment meets design standards and process requirements, ensures accurate experimental data, and reduces the risk of equipment failure, a temperature zone test is conducted before leaving the factory. | |

Precautions for using the equipment | 1. When the equipment furnace temperature is ≥300℃, it is forbidden to open the furnace to avoid getting hurt; 2. Slight cracks caused by continuous use of the furnace are normal and do not affect the normal use of the equipment;

| ||

Service support | 1-year warranty, lifetime support provided (excludes consumable parts from warranty). | ||

Disclaimer: The product introduction content on this site (including product images, product descriptions, technical parameters, etc.) is for reference only. There may be certain discrepancies between the stated content and the actual situation due to untimely updates. Please contact our customer service personnel for confirmation. The information provided on this site does not constitute any offer or commitment. Nobody Company reserves the right to improve and modify any information on the website from time to time without further notice.

推荐产品

Large capacity muffle furnace 1700℃

Vertical silent mixing ball mill

Box Type Thermogravimetric Analyser (TGA)

Constant temperature thermal fatigue testing machine

Anaerobic hot dip plating (quenching) system

Industrial vertical kiln

Vacuum storage cabinet

RTP rapid annealing furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China