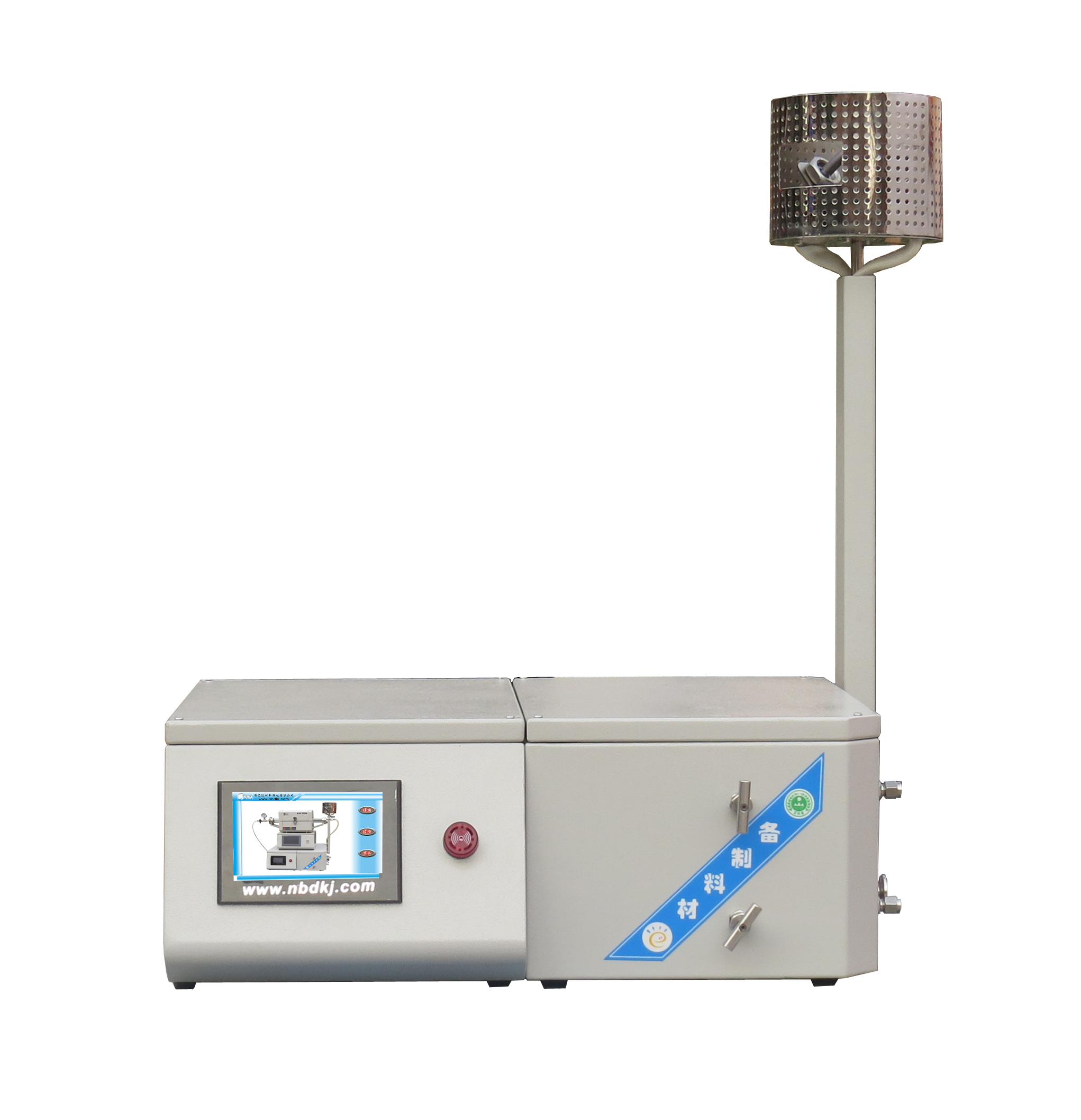

vacuum braze furnace

Release time: 2025-03-29 17:56:48 Number of views: 1058

Vacuum brazing furnace is a specialized equipment designed for brazing processes in high vacuum environments, widely used in aerospace, automotive manufacturing, electronics industry, precision machinery and other fields. This device ensures efficient welding of metal parts under non oxidizing conditions by precisely controlling the atmosphere conditions (such as vacuum environment) and temperature. Vacuum brazing furnace can significantly improve welding quality, reduce porosity and impurities in welds, and is suitable for applications with extremely high requirements for welding quality and aesthetics.

application area

1. Aerospace: used for manufacturing aircraft engine components, spacecraft structural components, etc.

2. Automotive manufacturing: used for producing key components such as high-performance engine components and transmissions.

3. Electronics industry: used for assembling precision components such as semiconductor chips and electronic packaging.

4. Precision machinery: used for manufacturing high-precision mechanical equipment such as clocks and medical devices.

5. Research and Education: Suitable for research and teaching experiments on material connection technology in universities, research institutes, and other research institutions.

| Equipment features:

| |||||||

Equipment name |

vacuum braze furnace | |||||||

Specification and model | VAH1600-200TIFGY(200*200*300) | |||||||

power supply | Three phase 380V 50HZ | |||||||

rated power | 45KW | |||||||

| Number of temperature zones | Single temperature and single control | |||||||

| sensor type | S-type thermocouple with a diameter of 8 * 300mm | |||||||

| rotameter | 20-200L/min | |||||||

| Tmax | 1300 ℃ (1200 ℃ at room temperature) | |||||||

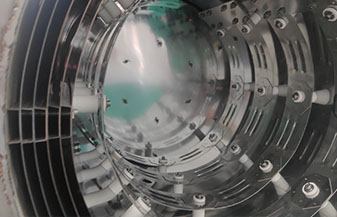

| Furnace material | 304不锈钢板+钼板 | |||||||

| Furnace size | Φ392*410mm | |||||||

| Effective working size | Length 200 * Height 200 * Depth 300mm | |||||||

| Recommended heating rate | ≤10℃/min | |||||||

| vacuum pump | BSV90 KF40 interface (maximum vacuum 4Pa) | |||||||

| molecular pump | Inlet CF200, outlet KF40 (ultimate vacuum 5 * 10 ^ -6Pa) | |||||||

| Ultimate vacuum of the whole machine | 6.7*10^-3Pa(Empty furnace, cold state) | |||||||

Furnace body size | Length 1835 * Height 2040 * Depth 1625mm | |||||||

Water cooling machine size | Length 706 * Height 1235 * Depth 1035mm | |||||||

control system |

| 1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set;

| ||||||

Temperature Accuracy | ±1℃ | |||||||

heating element |

|

Molybdenum strip heating furnace | ||||||

Pressure measurement and monitoring |

| Mechanical pressure gauges are used, and the gauge housing is of an airtight structure, which can effectively protect the internal components from environmental influences and debris intrusion. At the same time, it has strong corrosion resistance and high temperature resistance.

| ||||||

Gas supply system |   | The gas flow rate is controlled by a float flowmeter, which is integrated with the equipment and has undergone leak testing before leaving the factory. | ||||||

net weight | 约1215KG | |||||||

Equipment usage precautions |

When using the equipment, the absolute pressure gauge reading should not exceed 0.15MPa to prevent equipment damage caused by excessive pressure;

| |||||||

Service Support | One year limited warranty with lifetime support (warranty does not include consumable parts such as processing tubes and O-rings, please order replacement parts at the relevant product below). | |||||||

推荐产品

Vertical tube furnace (saturated steam)

Pressure rotary tube furnace

Intelligent Sintering Furnace AISF System (Automatic Intelligent Sintering Furnace)

Microwave muffle furnace

electric tablet machine

Three temperature zone gradient furnace

1200 ℃ large capacity intelligent box furnace (80L)

Gas safety protection device for tube furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China