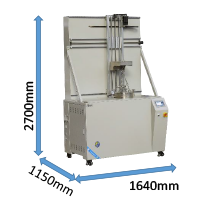

Pilot scale molten salt electroplating furnace

Release time: 2025-03-28 16:38:41 Number of views: 233

Equipment Introduction:

Molten salt furnaces are mainly used in the field of molten salt electrochemistry. High temperature molten salt, as an ion conductor, has a wide electrochemical window and fast reaction kinetics at high temperatures, making it an ideal electrolyte for electrochemical metallurgy. The electrolytic aluminum industry is a successful example of this. Based on this, we have developed a laboratory grade molten salt electroplating furnace to fill the market gap. The equipment adopts a lifting system, which can easily replace the reaction kettle to fully improve work efficiency.

| Equipment features: 1. High temperature sintering. saving and consumption reduction. mobile phones or computers. (the upper computer needs to install corresponding software).

| |

Equipment model | NBD-WG950-270T2DF10L-N | |

Equipment name | Pilot scale molten salt electroplating furnace | |

power supply | Three phase 380V 50HZ | |

rated power | 17KW | |

Number of temperature zones | Single temperature dual control | |

heating element | resistance wire | |

precision | ±1℃ | |

sensor type | K型热电偶 | |

Tmax | 1000℃ | |

Recommended heating rate | 10℃/Min | |

Temperature zone size and length | Φ350*640mm | |

Furnace tube material and size | 310s φ273*880/ GH3128 φ273*880 | |

Furnace body size | Length, height, and depth: 1640 * 2700 * 1150mm | |

weight | About 650KG | |

control system | 1. The NBD-101PE embedded operating system features a graphical interface for exchanging Chinese and English, a 7-inch true color touch screen input, and an intelligent human-machine dialogue mode; multiple process curves, each of which can be freely set; exporting to achieve paperless recording; temperature is nonlinearly corrected throughout the sintering process; temperature data from a computer.

| |

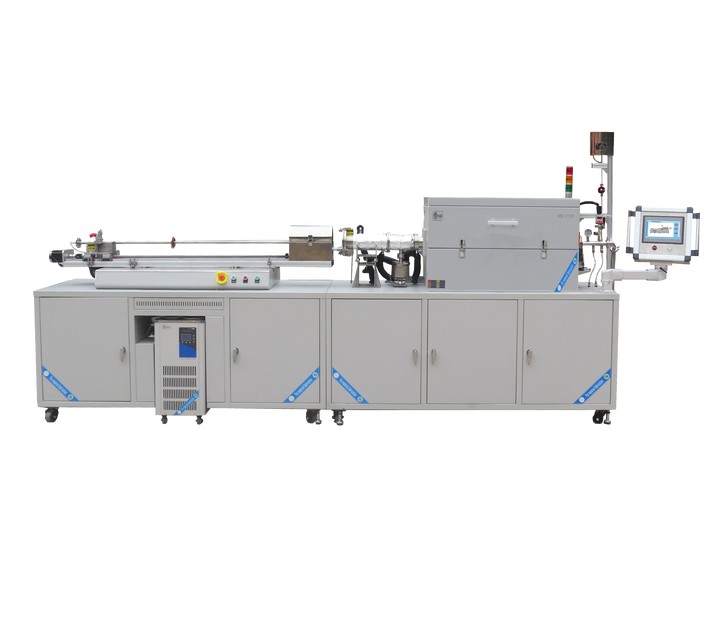

Stainless steel vacuum reaction chamber (water-cooled flange) |

| |

Service Support | 1-year warranty, providing lifetime service (warranty scope does not include consumable parts) | |

1-year warranty, providing lifetime service (warranty scope does not include consumable parts) Disclaimer: The product introduction content on this website (including product pictures, product descriptions, technical parameters, etc.) is for reference only. Due to delayed updates, there may be some discrepancies between the content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment. Nuobadi Company may periodically improve and modify any information on the website without prior notice.

Related products

| |||

推荐产品

Heat resistant material test furnace

Vacuum molten salt electrolysis furnace

Double layer industrial sintering furnace

High temperature tube furnace 1500℃

Automatic hydrogen reduction furnace Type III

ball mill tank

CVDO1200-XT33G2F

CVD系统O1200-MINI-G3Z

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China