Vacuum graphite heating furnace

Release time: 2025-03-27 23:40:21 Number of views: 236

Equipment Introduction:

The Nobadi vacuum graphite heating furnace has a compact structure and scientific design. The heating elements and insulation materials are made of high-purity graphite materials with different densities, and a built-in infrared thermometer is used as the temperature measurement and control device. Under the protection of gas environment, the equipment can reach 2650 ℃ for experiments such as graphitization, pyrolysis, silicification, tempering, brazing, degassing, carbonization, rapid prototyping, sintering, degreasing, synthesis, etc.

| Equipment features:

| |||||||

model | NBD-G2700-80TIGF | |||||||

Electrical specifications |

三相380V/50HZ | |||||||

Heating system | ||||||||

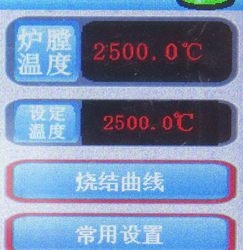

| Common working temperature | 2650℃ | |||||||

Common working temperature | 20KW | |||||||

| Furnace body size | L1000*H1270*W650mm | |||||||

| Main control heating rate | ≤5℃/min | |||||||

| Heating chamber size | 120*60*60mm | |||||||

| Effective volume (size) of graphite crucible | 7.7ml(50*22*7mm) | |||||||

| Heating and sample loading area |  | |||||||

| Real time display of ultra-high temperature |   | |||||||

Temperature measuring element | Dual color infrared thermometer resolution 0.1 ℃, repeatability ± 2 ℃, protection level IP65 | |||||||

| precision | ±1℃ | |||||||

| Main control insulation material | Pressing high-purity graphite hard felt | |||||||

| Structural operation mode | Upper opening heating with overall sealing, double-layer water-cooled furnace body and upper cover | |||||||

control system | ||||||||

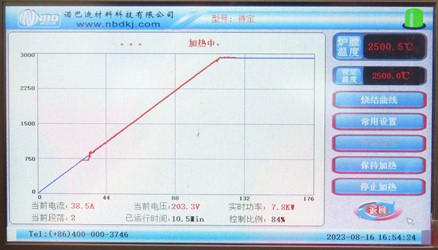

| Control mode | 、 1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set; 2. Pre order sintering is available to achieve unmanned sintering process curve sintering; 3. Real time display of sintering power, voltage and other information, recording of sintering data, and the ability to export for paperless recording; 4. Capable of remote control and real-time observation of equipment status; 5. Temperature correction: The difference between the main control temperature and the sample temperature is nonlinearly corrected throughout the sintering process.

| |||||||

| Temperature curve setting | Temperature curve setting | |||||||

| Temperature curve setting | The difference between the temperature controlled by the main controller and the temperature of the sample is corrected nonlinearly throughout the system (inquire with customers about commonly used temperature points for special validation) | |||||||

| data record | Real time monitoring, dynamic and realistic display of "time temperature curve" | |||||||

| system protection | Overtemperature alarm, overcurrent protection, disconnection prompt | |||||||

Gas supply system | ||||||||

| Flow meter type | 2-channel float flowmeter (mass flow controller can be selected according to experimental needs) | |||||||

| Gas pipeline core | Special stainless steel gas pipeline (1/4 ") | |||||||

| Type of regulating valve | Type of regulating valve | |||||||

| Normal condition of pipeline | normally closed | |||||||

| measurement accuracy | ±1.0%F.S | |||||||

| Linearity | ±0.5%F.S | |||||||

| repeatability | ±0.2%F.S | |||||||

| Pressure Range | -0.1-0.15 MPa | |||||||

| response time | 2S | |||||||

| Accuracy guarantee temperature | (15~35℃) | |||||||

| vacuum system | ||||||||

| High vacuum system |  | |||||||

| mechanical vacuum pump | Directly connected rotary vane vacuum pump (two-stage rotary vane) | |||||||

| Pumping speed | (10(L/s) | |||||||

| Inlet and exhaust connection port | KF16/25(mm) | |||||||

| Oil consumption | 0.6~1L | |||||||

| motor speed | 1440(rpm) | |||||||

| Ambient Temperature | 5~40℃ | |||||||

Noise (dB) | ≤56 | |||||||

| molecular pump | FJ-110molecular pump | |||||||

| pumping speed | 100(L/s) | |||||||

| rated speed | 4300 revolutions per minute | |||||||

| Cooling method | Air cooling/water cooling | |||||||

| other | ||||||||

| Vacuum gauge type | Simulated vacuum gauge | |||||||

| Overall ultimate vacuum of the system | 4.3×10-3Pa | |||||||

Service Support | One year limited warranty with lifetime support (warranty does not include consumable parts) | |||||||

Disclaimers

The product introduction content of this website (including product pictures, product descriptions, technical parameters, etc.) is for reference only. Due to delayed updates, there may be some discrepancies between the content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment. Nuobadi Company may periodically improve and modify any information on the website without prior notice.

Related products

|  |  | |

|  |  |  |

推荐产品

Anaerobic purification electrolytic furnace

Intelligent double temperature zone tube furnace 1500℃

High temperature tube furnace 1500℃

Intelligent double temperature zone tube furnace 1700℃

Vertical quenching furnace

Production-type atmosphere muffle furnace

3-way mass gas proportioner

High vacuum atmosphere muffle furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China