| Equipment features:

1. Independent temperature control in six temperature zones

Partition precise control: Six independent temperature zones are designed, each equipped with an independent PID controller, which can set and adjust the temperature separately, forming an accurate temperature gradient.

Flexible adjustment: Supports setting different heating rates, insulation times, and other parameters for different regions to meet complex

2.experimental or production process requirements.

Long term stability: The optimized design of the heating system and insulation layer ensures temperature uniformity and equipment lifespan during long-term high-temperature operation.

3. High precision temperature control

PID intelligent temperature control system: adopting advanced PID controller to ensure temperature control accuracy of ± 1 ° C, meeting temperature sensitive process requirements.

Real time monitoring: Equipped with high-precision temperature sensors, it monitors the temperature changes in each temperature zone in real time to ensure the consistency of process conditions.

4. Multiple atmospheric environments

Vacuum and atmosphere protection: supports operation under vacuum or inert gas (such as nitrogen, argon), reducing gas (such as hydrogen) environment,

5. Efficient heating system

Rapid heating: Advanced heating technology can achieve rapid heating, shorten preheating time, and improve work efficiency.

6. Safety and Maintenance

Over temperature protection: Built in over temperature protection device, automatically cuts off power when the temperature rises abnormally, preventing equipment damage.

Emergency stop button: Set up a clear emergency stop button to ensure the safety of operators.

Regular maintenance reminder: The system can set regular maintenance reminders to help users perform equipment maintenance in a timely manner and extend its service life.

7. Data recording and analysis

Real time monitoring: The built-in data acquisition system can record key parameters such as temperature and atmosphere composition in each temperature zone in real time, facilitating subsequent analysis.

Data analysis software: Provides professional data analysis software, supports automatic report generation, and allows exporting data for in-depth analysis.

|

Equipment name | 1500 degree six temperature zone tube furnace |

Specification and model | NBD-T1500-200T3Z |

power supply | 三相380V 50HZ |

rated power | 36KW |

Number of temperature zones | Single temperature six control |

Temperature zone size | 1430mm in length, 260mm in height, and 240mm in depth |

precision | ±1℃ |

sensor type | S-type thermocouple with a diameter of 8 * 270mm |

巡检热电偶 | S-type thermocouple with a diameter of 8 * 400mm |

Tmax | 1500℃ |

Continuous operating temperature | 1380℃ |

Recommended heating rate | ≤3℃/min |

Furnace tube material | rbsc |

Furnace tube size | Flange with a diameter of 240 * outer diameter of 200 * length of 2150 * wall thickness of 10mm |

Outer dimensions of crucible | Length 160mm * Height 70mm * Depth 160mm (Thickness 8mm) |

Collection tank capacity | 10L |

Washing cylinder capacity | 10L |

Upper cover opening method | Electric opening and closing maximum angle 45 ° |

Mass flow controller 1 | S500 10SLM with a diameter of 6.35 and dual card sleeve fluororubber sealing nitrogen calibration |

Mass flow controller 2 | S500 15SLM with a diameter of 6.35 and dual card sleeve fluororubber sealing nitrogen calibration |

Mass flow controller 3 | S500 15SLM with a diameter of 6.35 and dual card sleeve fluororubber sealing nitrogen calibration |

vacuum pump | VRD-16 single-phase 220V/50HZ KF25 pumping speed 4.4L/s motor speed 1440rpm |

water chiller | CW-5300 AC220V/50HZ water tank capacity 10L |

Furnace body size | Length 3110 * Height 1400 * Depth 1000mm |

weight | About 670KG |

| control system |

| 1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set;

2. Pre order sintering is available to achieve unmanned sintering process curve sintering;

3. Real time display of sintering power, voltage and other information, recording of sintering data, and the ability to export for paperless recording;

4. Capable of remote control and real-time observation of equipment status;

5. Temperature correction: The difference between the main control temperature and the sample temperature is nonlinearly corrected throughout the sintering process.

|

| heating element |

| High purity silicon carbide rod

|

Corrosion resistant silicon carbide furnace tube |

| Silicon carbide has good resistance to most acids and bases, making it suitable for use in various atmospheres, including corrosive gas environments. |

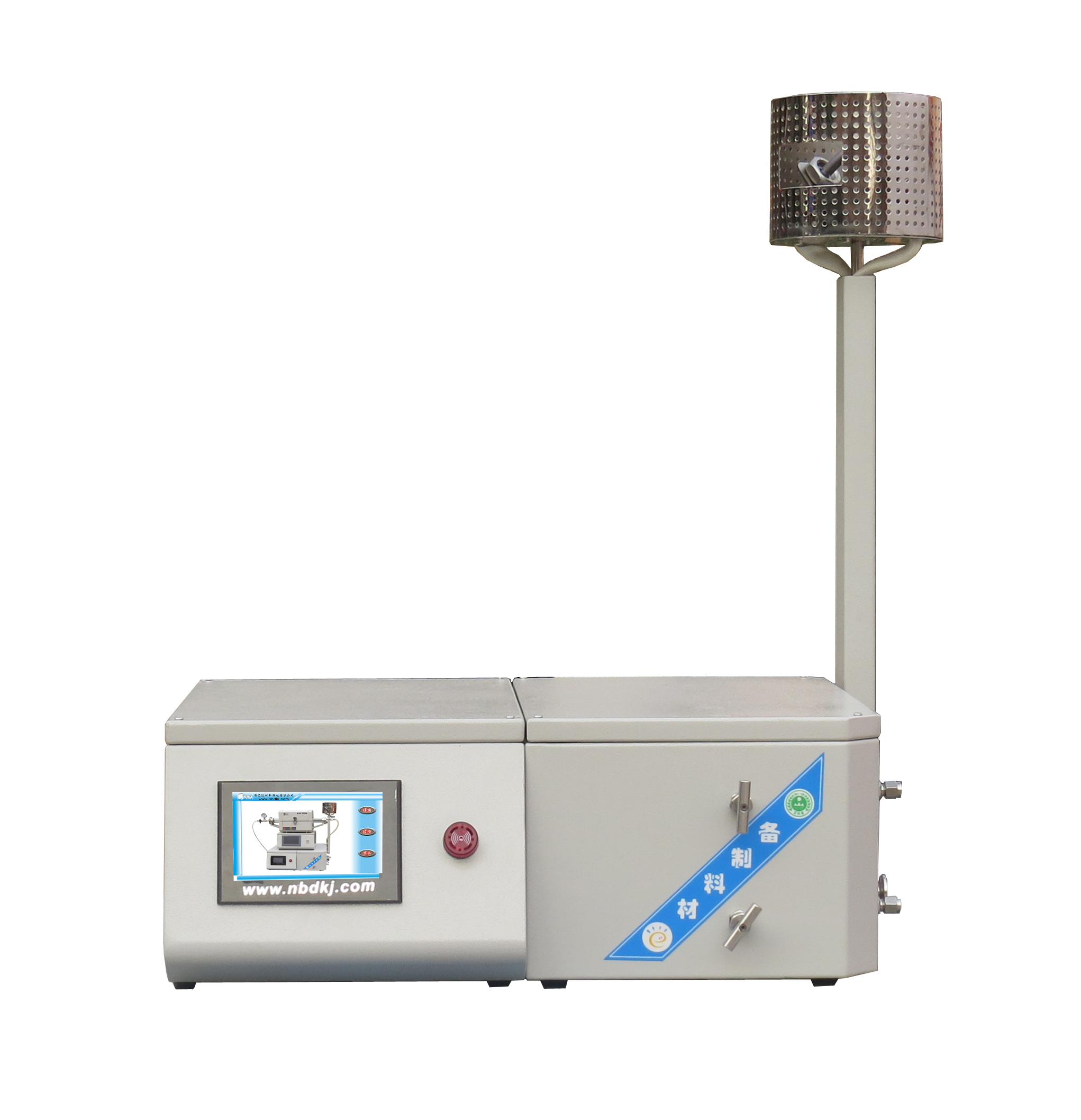

Condensation collector

|

| The condenser collector is made of 304 stainless steel material and has a built-in water-cooled structure. It condenses the metal vapor brought out by the molecular pump or airflow, reduces the temperature of the reaction mixture, and prevents the generation of by-products. Avoid causing damage to the molecular pump unit.

|

Pressure measurement and monitoring

|

| Mechanical pressure gauges are used, and the gauge housing is of an airtight structure, which can effectively protect the internal components from environmental influences and debris intrusion. At the same time, it has strong corrosion resistance and high temperature resistance.

|

Gas supply system

|

| The gas flow rate is controlled by a float flowmeter, which is integrated with the equipment and has undergone leak testing before leaving the factory.

|

.jpg)