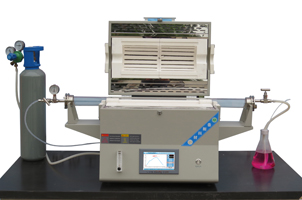

Bridgman crystal growth furnace

Release time: 2025-03-12 19:18:38 Number of views: 188

The Bridgman crystal growth furnace is an equipment used for preparing high-quality single crystal materials, particularly suitable for growing single crystals of materials such as semiconductors, metals, and ceramics. This furnace achieves crystal growth by controlling the temperature gradient and material cooling rate. This device combines the technologies of "vertical crucible descent, furnace movement" and "rotating pulling", which is a relatively advanced configuration that improves the quality and uniformity of crystal growth.

| Equipment features:

| ||

Equipment name | Bridgeman single crystal growth furnace | ||

Equipment model | LO1700-100T2F | ||

power supply | AC380V 50Hz | ||

maximum power | 9.5KW | ||

Tmax | 1650℃(<1小时) | ||

Continuous operating temperature | 1600℃ | ||

heating element | Silicon molybdenum rod | ||

Furnace tube flange | 99 corundum tube size Φ 100 * 1300mm (operating temperature < 1700 ℃)

| ||

sample stage | Φ 80mm graphite sample stage

| ||

Crucible loading | Automatic sample table lifting for easy placement/sampling of crucibles

| ||

heating zone | Dual temperature zone, with a length of 100+100mm | ||

temperature control system | Adopting PID method for temperature control, adjustable temperature rise and fall programs can be set

| ||

precision | ±1℃ | ||

thermocouple | B-type thermocouple | ||

Furnace body movement stroke and speed | The maximum movement stroke of the furnace body is 300mm

| ||

|

|

| |

推荐产品

Homogeneous oxidation diffusion furnace (Type I)

Large capacity muffle furnace 1700℃

Crucible for zirconia sintering

Single temperature zone tube furnace 1200℃

Button type battery slicer

Multi channel gas self-control controller

Intelligent muffle furnace (12L)1200℃

Box type crystallizing furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China