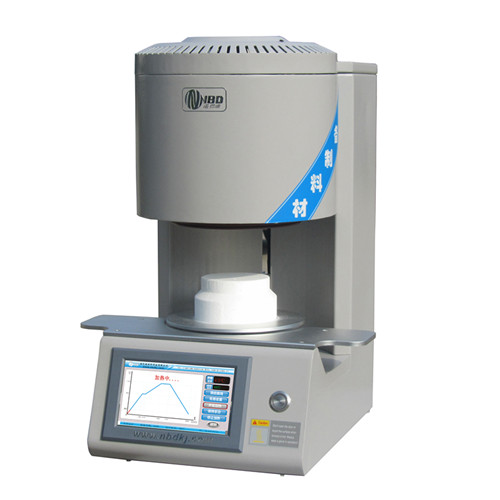

Experimental apparatus for reducing and extracting alloy preparation

Release time: 2025-02-22 16:53:46 Number of views: 1125

The experimental device for preparing alloy by reduction extraction is a high-temperature heating equipment designed specifically for laboratories, mainly used for preparing various alloy materials by reduction extraction method. This heating furnace is capable of conducting reduction reactions and alloying processes of metal oxides in high-temperature environments (usually up to 1200℃), and is suitable for research and development in fields such as materials science, metallurgical engineering, and chemical engineering.

| Equipment features Precise control: PID temperature control technology and high-precision sensors are used to ensure consistency and repeatability of reaction conditions. Multi step process integration: Integrating multiple steps such as reduction and extraction into one system to simplify the operation process and improve efficiency. Efficient Separation: Optimize the extraction process, utilize different physical and chemical properties to achieve effective separation, and reduce impurity content. High degree of automation: Supports programming control and remote monitoring, allowing users to set process parameters through a computer interface and monitor experimental progress in real-time. Flexible configuration: Different specifications of reactors, gas flow rates, and other parameters can be customized according to specific experimental needs to meet diverse research needs. | ||

Equipment name | Experimental apparatus for reducing and extracting alloy preparation | ||

power supply | Single phase 220V 50HZ | ||

rated power | 6KW (including 2KW molecular pump unit) | ||

heating element | HRE alloy resistance wire | ||

Furnace temperature control accuracy | ±1℃ | ||

Temperature control sensor (furnace) | K-type thermocouple with a diameter of 2 * 420mm | ||

Temperature control accuracy of reaction kettle | ±5℃ | ||

Temperature sensor (reactor) | K-type right angle thermocouple with a diameter of 8mm * 100+450 | ||

Tmax | 1200℃ | ||

rated temperature | 1150℃ | ||

Recommended heating rate | ≤20℃/min | ||

Size of furnace temperature zone | φ240*220mm | ||

Sintering crucible size | Outer diameter of 133mm, height of 180mm (at 1100 ℃) | ||

Collect crucible dimensions | Outer diameter of 120, inner diameter of 34.5, height of 30 (at 200-300 ℃) | ||

Molecular pump unit power supply | 380V 50HZ | ||

Vacuum pump model | DRV30 KF40 connector extraction speed of 8.3L/s | ||

Molecular pump model | FF-160/620F LF interface with a pumping speed of 600L/s and a speed of 27000 r/min | ||

Overall ultimate vacuum degree of the system | ≤5.3×10-4Pa | ||

Furnace body size | Length 1150 * Height 1480 * Depth 700mm | ||

Furnace weight | About 200KG | ||

control system |

| 1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set; 2. Pre order sintering is available to achieve unmanned sintering process curve sintering; 3. Real time display of sintering power, voltage and other information, recording of sintering data, and the ability to export for paperless recording; 4. Capable of remote control and real-time observation of equipment status; 5. Temperature correction: The difference between the main control temperature and the sample temperature is nonlinearly corrected throughout the sintering process.

| |

heating element |   | HRE alloy resistance wire | |

| condenser |   | The condenser collector is made of 304 stainless steel material and has a built-in water-cooled structure. It condenses the metal vapor brought out by the molecular pump or airflow, reduces the temperature of the reaction mixture, and prevents the generation of by-products. Avoid causing damage to the molecular pump unit. | |

| Equipment usage precautions |

1.When the furnace temperature of the equipment is ≥ 300 ℃, it is forbidden to open the furnace to avoid injury; 2.Minor cracks caused by continuous use of the furnace are a normal phenomenon and do not affect the normal use of the equipment;

| ||

| Service Support | One year limited warranty with lifetime support (warranty does not include consumable parts) | ||

Metallurgical industry: Reduction treatment of metal powders to prepare high-performance alloys, applied in aerospace, automotive manufacturing and other fields.

Chemical engineering: studying the laws of substance transformation in complex systems and optimizing production processes.

Environmental Science: Exploring effective recycling methods for valuable metals in waste electronic devices to promote resource recycling.

推荐产品

Bottom-loading high temperature sintering furnace

Intelligent Chamber Furnace (7.2L) 1200°C

Two float proportioners

NOBODY tube furnace, box furnace type naming rules

In situ observation of molten salt electroplating furnace

High temperature and high pressure tube furnace

Double temperature rapid annealing slide furnace

Mini vacuum atmosphere furnace (box tube furnace)

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China