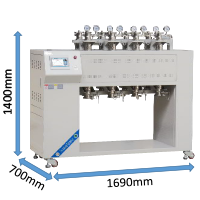

Vertical eight channel high-throughput tube furnace

Release time: 2025-02-11 22:13:05 Number of views: 234

Equipment Introduction:

The vertical eight channel high-throughput tube furnace is a high-temperature processing equipment designed for simultaneously processing multiple samples or continuous materials, widely used in materials science, chemical engineering, metallurgy, nanomaterial preparation, ceramic sintering, catalytic research and other fields.

Having eight parallel heating tube channels, heating experiments can be conducted independently or simultaneously, improving experimental efficiency and throughput, while also allowing for comparative experiments to enhance data reliability and reproducibility.

|

Equipment features

| |||||||

Equipment name | Vertical eight channel high-throughput tube furnace | |||||||

Specification and model | NBD-LT1200-LTS-MC8 | |||||||

Tmax | 1150℃ | |||||||

heating rate | 1℃/H-20℃/Min | |||||||

rated power | 12kw | |||||||

power supply | three-phase380V 50HZ | |||||||

Number of temperature zones | Eight temperature and eight control | |||||||

sensor type | K type thermocouple | |||||||

Temperature zone size | Inner diameter * height Φ 80 * 200mm | |||||||

Furnace tube size |

1690*1400*700(Length * Height * Depthmm) | |||||||

control system |

|

1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set;

| ||||||

Temperature Accuracy | ±1℃ | |||||||

Equipment Details |  | |||||||

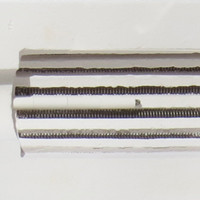

heating element |

| Mo doped Fe Cr Al alloy | ||||||

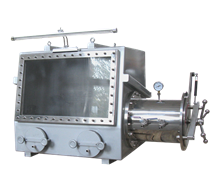

SEALING SYSTEM | |

|

| |||||

Vacuum degree: 10Pa (mechanical pump) | ||||||||

Pressure measurement and monitoring | | Mechanical pressure gauges are used, and the gauge housing is of an airtight structure, which can effectively protect the internal components from environmental influences and debris intrusion. At the same time, it has strong corrosion resistance and high temperature resistance.

| ||||||

Gas supply system |

| The gas flow rate is controlled by a float flowmeter, which is integrated with the equipment and has undergone leak testing before leaving the factory.

| ||||||

net weight | 260kg | |||||||

Equipment usage precautions |

When using the equipment, the absolute pressure gauge reading should not exceed 0.15MPa to prevent equipment damage caused by excessive pressure;

| |||||||

Service Support | One year limited warranty with lifetime support (warranty does not include consumable parts such as processing tubes and O-rings, please order replacement parts at the relevant product below). | |||||||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to delayed updates, there may be some discrepancies between the content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment. Nuobadi Company may periodically improve and modify any information on the website without prior notice.

推荐产品

Glove box matching transition furnace

Horizontal vacuum atmosphere furnace

High temperature physical property test system

Small CVD system

Sliding rail mobile fast annealing furnace

High vacuum atmosphere muffle furnace

TGB-2 Vacuum glove box

Ultra-high temp. heating furnace 2000℃

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China