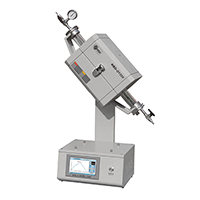

Open Mini Rotary Stove

Release time: 2025-02-11 18:42:06 Number of views: 200

The Mini Rotatable 90 ° Open Tube Furnace is a small high-temperature processing equipment specifically designed for laboratory environments. It is particularly suitable for experiments such as material synthesis, heat treatment, and annealing that require controlled or vacuum atmospheres. The main feature of this device is its unique rotatable design, which allows the furnace body to rotate 90 degrees along the axis, facilitating the loading and unloading of samples. In addition, the mini size design makes it very suitable for use in laboratories with limited space.

|

Equipment features: process, ensuring operational safety. 2. Precise temperature control preset parameters. stable and reliable process conditions. treatment under anaerobic or other specific atmospheric conditions. stable atmosphere and prevent sample oxidation or reaction. improve production efficiency. is detected to prevent equipment damage. action in case of emergencies. simplifies operation process and improves automation level. equipment status at any time.

| ||||||||

Electrical specifications | NBD-O1200-50TIR | ||||||||

Electrical specifications | AC220V 1.0KW | ||||||||

Reachable temperature | 1200 ℃ (<1 hour) | ||||||||

rated temperature | 1150℃ | ||||||||

Long term use temperature range | 300~1150℃ | ||||||||

heating rate | 1℃/H-20℃/Min | ||||||||

Furnace tube diameter | 50mm | ||||||||

Furnace body size | 350×390×350mm | ||||||||

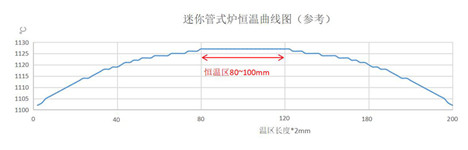

Temperature field distribution |

| As shown in the figure: This is the temperature zone curve of the device (constant temperature zone size: 100mm) | |||||||

Temperature Accuracy | ±1℃ | ||||||||

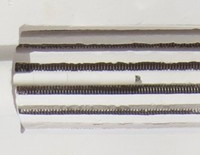

heating element |

| Mo doped Fe Cr Al alloy | |||||||

| control system |  | 1. 15 temperature curves can be pre stored to avoid the trouble caused by repeated settings of different experimental processes; 2. The experimental process is more intuitive and the operation is more convenient;3. The NBD-101E embedded operating system has a graphical interface for exchanging Chinese and English,7-inch true color touch screen input, intelligent human-machine dialogue mode, non-linear style temperature correction; 4. It has functions such as over temperature alarm, disconnection prompt, and leakage protection.

| |||||||

SEALING SYSTEM |

|

|

| ||||||

Vacuum degree: 10Pa (mechanical pump) | |||||||||

Pressure measurement and monitoring |

| Mechanical pressure gauges are used, and the gauge housing is of an airtight structure, which can effectively protect the internal components from environmental influences and debris intrusion. At the same time, it has strong corrosion resistance and high temperature resistance.

| |||||||

net weight | 30kg | ||||||||

Equipment usage precautions |

1. When the furnace temperature of the equipment is ≥ 300 ℃, it is forbidden to open the furnace to avoid injury; to prevent equipment damage caused by excessive pressure; a pressure reducing valve must be installed on the cylinder. It is recommended to purchase a small pressure reducing valve for testing, with a range of 0.01MPa-0.15MPa, which will be more precise and safe to use; The pressure inside the furnace tube should be equivalent to atmospheric pressure and maintained at atmospheric pressure; experiments. If it is necessary to close the gas valve to heat the sample, it is necessary to constantly monitor the reading on the pressure gauge. If the absolute pressure gauge reading is greater than 0.15 MPa, the exhaust valve must be immediately opened to prevent accidents (such as furnace tube rupture, flange flying out, etc.).

| ||||||||

Service Support | One year limited warranty with lifetime support (warranty does not include consumable parts such as processing tubes and O-rings, please order replacement parts at the relevant product below). | ||||||||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.)

is for reference only. Due to delayed updates, there may be some discrepancies between the content and the actual situation. Please contact

our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment. Nuobadi

Company may periodically improve and modify any information on the website without prior notice.

推荐产品

CVD system O1200-XTID3F

Vertical tube furnace (saturated steam)

Intelligent Sintering Furnace AISF System (Automatic Intelligent Sintering Furnace)

High pressure hydrogen preheating and blowing system

steam generator

0.2L melting furnace 1200℃

Multi channel gas self-control controller

Microwave muffle furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China