Small tube furnace 1500/1700 ℃

Release time: 2025-02-08 00:08:38 Number of views: 184

Small vacuum tube furnaces are widely used in various CVD experiments, as well as in research fields such as vacuum sintering, atmosphere protected sintering, nanomaterial preparation, and battery material preparation. Nuobadi not only strictly controls product quality, but also pays great attention to customer experience, considering every detail of customer use to make operation more convenient!

| Equipment features: | ||||||||||

PRODUCT MODEL | NBD-T1500-50TI | NBD-T1700-50TI | |||||||||

Electrical specifications | AC220V 1.5KW | AC220V 1.8KW | |||||||||

Reachable temperature | 1500 ℃ (<1 hour) | 1700 ℃ (<1 hour) | |||||||||

Continuous temperature | 1450 ℃ (continuous) | 1650 ℃ (continuous) | |||||||||

Achievable heating rate | ≤ 20 ℃/min | ||||||||||

Heating zone length | 180mm | ||||||||||

Furnace tube size | Φ50*700mm | ||||||||||

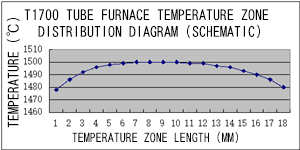

Temperature field distribution |

| As shown in the figure: This is the temperature zone curve of the 1700 ℃ equipment | |||||||||

control system |

| 1. The NBD-101E embedded operating system features a graphical interface for exchanging Chinese and English, a 7-inch true color touch screen input, an intelligent human-machine dialogue mode, real-time heating power display, and non-linear temperature correction;

| |||||||||

| Pressure measurement and monitoring |  | Mechanical pressure gauges are used, and the gauge housing is of an airtight structure, which can effectively protect the internal components from environmental influences and debris intrusion. At the same time, it has strong corrosion resistance and high temperature resistance. | |||||||||

| Gas supply system |  | The gas flow rate is controlled by a float flowmeter, which is integrated with the equipment and has undergone leak testing before leaving the factory. | |||||||||

Temperature Accuracy | +/- 1 ℃ | ||||||||||

heating element |

High purity silicon carbide rod |

High purity silicon molybdenum rod | |||||||||

SEALING SYSTEM |

|

|

| ||||||||

Vacuum degree: ≤ 10Pa (mechanical pump) | |||||||||||

Pressure measurement and monitoring |

| | |||||||||

Gas supply system |

| The gas flow rate is controlled by a float flowmeter, which is integrated with the equipment and has undergone leak testing before leaving the factory. | |||||||||

net weight | 30KG | 45KG | |||||||||

Equipment usage precautions | 1、When using the equipment, the absolute pressure gauge reading should not exceed 0.15MPa to prevent equipment damage caused by excessive pressure; | ||||||||||

Service Support | 1-year warranty with lifetime support (warranty does not include consumable parts such as furnace tubes and seals). | ||||||||||

Related products

推荐产品

RTP rapid steaming sintering furnace

Constant pressure vacuum rotary pendulum sintering furnace

In situ observation of molten salt electroplating furnace

Automatic hydrogen making machine H1000

PECVD system

High temperature physical property test system

Well type molten salt electroplating furnace

Cooling circulator

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China