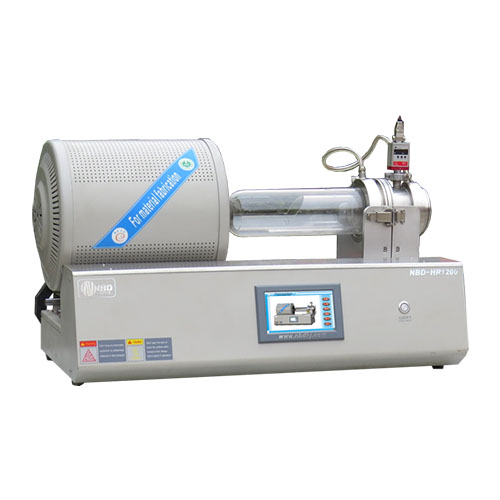

Vertical homogenization melting furnace

Release time: 2025-02-06 00:28:51 Number of views: 149

Equipment Introduction:

This equipment is equipped with an automatic feeding system, where materials are melted in a vacuum, inert gas protection, or reactive gas environment. The sealed rotating hoisting mechanism completes the automatic feeding, melting, chemical reaction, homogenization, and other processes of the materials under the coordination of pulse gas. At the same time, the high-purity quartz observation window can observe the material status in real time.

The 7-inch full touch screen intelligent human-machine interaction system is easy and intuitive to operate, equipped with a combustible exhaust automatic ignition system to ensure the safety and stability of the entire process.

| Equipment features: 1. The collection device is equipped with a double-layer water cooling system, which can greatly improve the cooling and collection efficiency of materials; 2. The control system adopts advanced PLC+touch screen control system, which makes the operation simpler and more convenient. The control mathematical model adopts advanced PID self-learning fuzzy control to maintain the temperature control accuracy at ± 1 ℃; 3. The furnace body adopts a double-layer air-cooled structure technology, which helps to reduce the surface temperature of the shell; 4. High purity Al2O3 fiber refractory insulation material has superior insulation effect and effectively reduces equipment power consumption; 5. The heating elements are distributed in a circular shape inside the furnace, surrounding the furnace tube 360 degrees to improve the temperature uniformity inside the furnace. | ||||||||||||||

Product model | NBD-G1200-26TI2F-350 | ||||||||||||||

Electrical specifications | Three phase 380V 50HZ | ||||||||||||||

Maximum operating temperature |

1150℃ | ||||||||||||||

rated power | 12KW | ||||||||||||||

Type of temperature measuring element | K-type thermocouple 420mm | ||||||||||||||

Heating temperature zone size | φ350*420mm | ||||||||||||||

| Furnace tube material | 310s stainless steel pipe | ||||||||||||||

| Effective volume of furnace tube | 70L | ||||||||||||||

| Mixing motor speed | 0~11 revolutions per minute | ||||||||||||||

| Cutting motor speed | 0~19 revolutions per minute | ||||||||||||||

| Furnace body size | Length 1430 x Depth 1060 x Height 2560mm | ||||||||||||||

Recommended heating rate | 10℃/min | ||||||||||||||

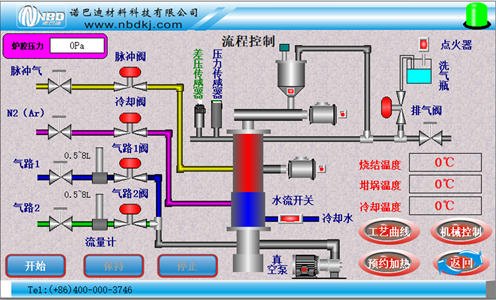

Main control interface |

| ||||||||||||||

| Touch screen control system |

1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set; | ||||||||||||||

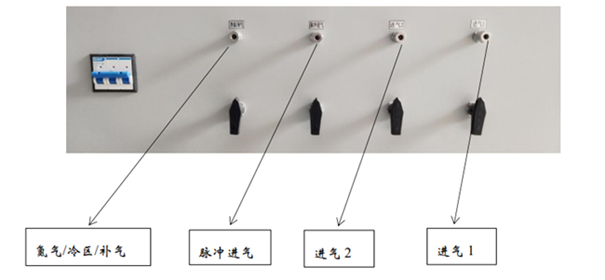

| pneumatic system |

| ||||||||||||||

precision | ±1 ℃ | ||||||||||||||

High definition quartz observation window for working cavity |

| ||||||||||||||

压力测量与监控 |

| | |||||||||||||

供气系统 |   | The gas flow rate is controlled by a float flowmeter, which is integrated with the equipment and has undergone leak testing before leaving the factory. | |||||||||||||

| weight | About 650KG | ||||||||||||||

Equipment usage precautions |

| ||||||||||||||

Service Support | 1-year warranty with lifetime support (warranty does not include consumable parts such as furnace tubes and seals, etc.)) | ||||||||||||||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to delayed updates, there may be some discrepancies between the content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment. Nuobadi Company may periodically improve and modify any information on the website without prior notice.

推荐产品

Large bell jar sintering furnace

Small CVD system

CVDO1200-XTIG3Z

0.2L melting furnace 1200℃

bottom-loading zirconia furnace

RTP rapid annealing furnace

Anticorrosive mini muffle furnace

Universal testing machine with heating furnace (Type A)

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China