| Equipment features:

1. Efficient microwave heating

Rapid heating: Microwave heating can directly act on the interior of the material, achieving rapid heating and shortening heating time.

Uniform heating: Microwave energy can penetrate the material evenly, ensuring uniform temperature distribution and avoiding local overheating.

• Energy saving and efficient: Microwave heating has a high energy utilization rate and is more energy-efficient compared to traditional heating methods.

2. Precise control

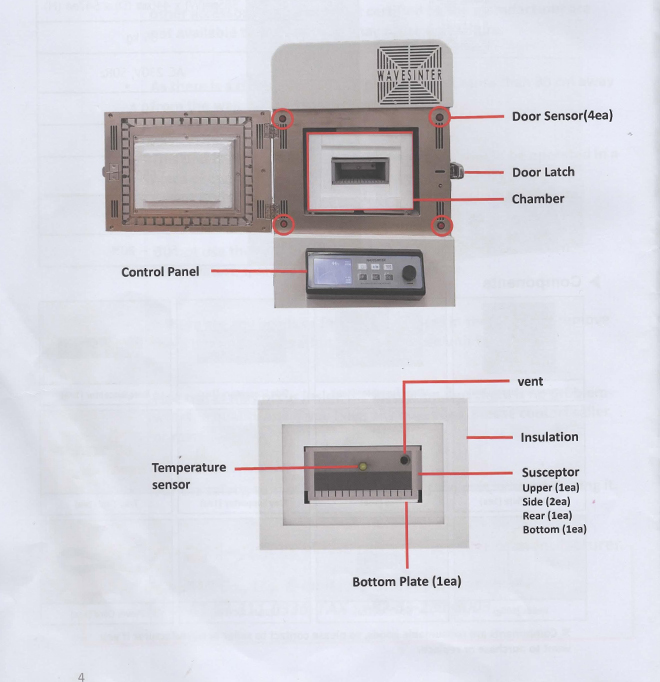

Real time monitoring: Equipped with high-precision temperature sensors, real-time monitoring of temperature changes inside the furnace, and feedback to the temperature control system for adjustment.

User friendly: With a user-friendly interface, it is easy to operate and maintain.

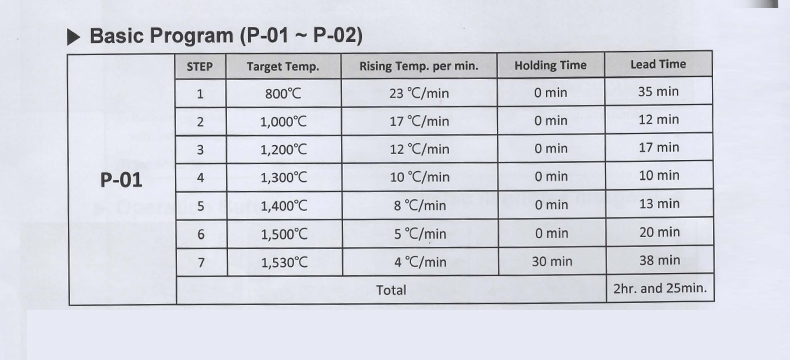

Program storage: Multiple heating programs can be set and saved for easy reuse.

3. Safety design

Multiple protection measures: Built in over temperature protection, over-current protection and other multiple safety protection measures ensure safe operation.

Emergency stop function: can quickly cut off the power in case of abnormal situations, ensuring the safety of personnel and equipment

|

Equipment usage precautions | 1. Microwave source equipment operates under high voltage and has high requirements for the working environment. It should be avoided to use it in places with high humidity and dust.

2. Improper operation and use of microwave source equipment may pose a risk of high-voltage electric shock and microwave radiation; The high voltage of microwave sources can be fatal, therefore, the operators of microwave source equipment must be personnel who have undergone strict professional training and possess relevant knowledge and experience.

When maintaining the high-voltage power supply, even if the power switch is disconnected, residual voltage will still be maintained in the equipment. If necessary, the high-voltage capacitor should be short circuited and discharged.

Before each use of the microwave source, all safety systems must be properly in place and functioning properly.

5. It is mandatory to regularly detect microwave leaks at a distance of 5 centimeters from the measurement point, and under normal working conditions, the microwave leakage should not exceed 5mW/cm3. If the specified value is exceeded, troubleshooting should be carried out according to the instructions in the manual.

6. Before each use, the microwave source equipment must be checked and ensured that the water cooling circulation system is turned on and in normal working condition. Otherwise, it cannot be turned on to avoid damage to the microwave source.

7. The cooling circulating water used for microwave sources should meet the water quality requirements in GB10067.1-88, with a total hardness (CaO mg equivalent) of less than 10, an inlet temperature of 5-30 ℃, an outlet temperature of less than 50 ℃, and a working pressure of 0.06-0.12MPa. The cooling water circuit should be cleaned regularly (it is recommended to clean it every three months). If the cooling water circuit is blocked, it will cause the magnetron to overheat, shorten its service life, and even burn out.

8. Microwave sources are highly susceptible to damage when operating under conditions of overcurrent, overvoltage, high-power, and poor cooling, especially their core component magnetron, which is very delicate and expensive. Therefore, the anode current of the equipment should be controlled below the rated value during long-term operation to ensure the service life of the magnetron.

9. It is necessary to regularly clean the microwave sintering furnace cavity to remove all deposits, including waveguide windows; Remove mixed metals and other foreign objects that may cause arcing. Sediments at waveguide windows, blind plates, etc. should be regularly cleaned with alcohol and kept clean. If the waveguide window is contaminated, it will cause microwave energy to be blocked and unable to enter the sintering furnace, or generate strong heat on its surface, and even high-frequency ignition phenomenon. In severe cases, it will damage the microwave source.

10. When sintering volatile and corrosive materials, the impact of the materials on the equipment and protective measures should be fully considered; Special attention should be paid to the impact of material volatilization on waveguide windows, observation windows, blind plates, and temperature measurement windows during the sintering process.

|