Multi channel liquid gas-phase generator

Release time: 2024-10-31 15:09:39 Number of views: 421

Equipment Introduction:

A multi-channel liquid gas phase generator is a device used to convert liquid into gas phase, capable of processing multiple liquid samples simultaneously. Each channel is independently controlled and suitable for batch sample processing. Widely used in various fields such as chemical analysis, environmental monitoring, pharmaceutical industry, materials science, etc.

This device converts liquid samples into stable gas phase output by precisely controlling the evaporation process of the liquid, making it suitable for experimental and industrial applications that require high-precision gas phase supply.

Application areas:

1. Chemical analysis: an injection system used for analytical instruments such as gas chromatography (GC) and mass spectrometry (MS).

2. Environmental monitoring: used for detecting volatile organic compounds (VOCs) in air pollutants and water quality analysis.

3. Pharmaceutical industry: used for drug composition analysis, drug stability research, etc.

4. Materials Science: Used for the analysis of volatile components in materials such as polymers and coatings.

5. Food Science: Used for the analysis of food aroma and flavor components.

| Equipment features: | |||||||

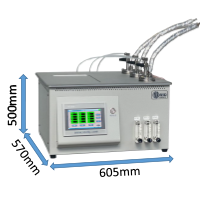

| Equipment name | Liquid gas phase generator | |||||||

Specification and model | NBD-TS0.1LZ3 | |||||||

power supply | Single phase 220V 50HZ | |||||||

rated power | 4KW | |||||||

sensor type | K-type thermocouple with a diameter of 1*350mm | |||||||

| Tmax | 400℃ | |||||||

Furnace size | φ90*100mm | |||||||

Furnace body size | L605*H500*W570mm | |||||||

control system |

| 1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set; 2. Pre order sintering is available to achieve unmanned sintering process curve sintering; 3. Real time display of sintering power, voltage and other information, recording of sintering data, and the ability to export for paperless recording; 4. Capable of remote control and real-time observation of equipment status; 5. Temperature correction: The difference between the main control temperature and the sample temperature is nonlinearly corrected throughout the sintering process. | ||||||

Temperature Accuracy | ±1℃ | |||||||

heating element |

| Mo doped Fe Cr Al alloy | ||||||

Gas supply system |   | The gas flow rate is controlled by a float flowmeter, which is integrated with the equipment for easy control, and a leak test has been conducted before leaving the factory. | ||||||

net weight | 35KG | |||||||

Equipment usage precautions | ★ Users are not allowed to modify the device without authorization; | |||||||

Service Support | One year limited warranty, providing lifetime support (the warranty does not include consumable parts such as processing tubes and O-rings, please order replacement parts at the relevant product below) | |||||||

推荐产品

High vacuum atmosphere muffle furnace

1500℃ large capacity muffle furnace

Heating-zone automatic tester

Button type battery slicer

ball mill tank

3C vacuum pump

NBD-LT cold and thermal fatigue testing machine

Open Mini Rotary Stove

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China