Medium vacuum atmosphere pendulum rotary sintering furnace 1200℃

Release time: 2017-11-15 14:31:15 Number of views: 7601

Vacuum atmosphere rotary furnace is a powder heat treatment equipment with high degree of automation, which can be used for lithium battery anode and cathode materials, rare earth materials, chemical catalysts, magnetic materials, powder hydrogen reduction and other aspects of material heat treatment preparation. The equipment can be tilted and continuously rotated. The material lifting scraper structure is placed in high purity quartz tube to ensure the uniform heating of materials and guarantee the sintering effect.

Configuration

| 1. The material will roll radial and axial under the rotating pendulum vibration of the reaction chamber to ensure uniform heating of the material and adequate contact with the gas to prevent overburning and entraining caused by static sintering; 4. The product uses automatic control mode, equipped with 7-inch touch screen real-time tracking display device status; | |||||||||||||||

Model | NBD-RT1200-100TI | NBD-RT1200-100T2 | NBD-RT1200-100T3 | |||||||||||||

Electrical Spec | AC220V 4KW | AC220V 4KW | AC220V 6KW | |||||||||||||

Tmax | 1200 ℃ | |||||||||||||||

Max working temps. | 1100 ℃ | |||||||||||||||

Heating rate | ≤ 20 ℃/min | |||||||||||||||

Heating length | 440mm | 200mm*2(Single heating zone & 2-control) | 200mm*3(Single temperature and 3- control) | |||||||||||||

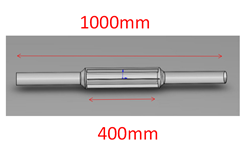

Tube size |

| |||||||||||||||

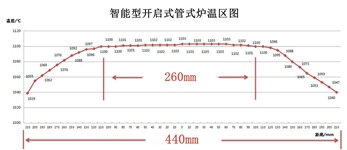

Temperature field distribution |

| As shown in the figure, this is the temperature zone curve of the equipment with single and double temperature zones | ||||||||||||||

Control system |

| 1. 15 temperature curves can be pre-stored to avoid the trouble caused by repeated setting of different experimental processes; | ||||||||||||||

Temp Accuracy | +/- 1 ℃ | |||||||||||||||

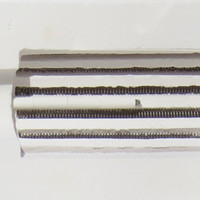

Heating element |

| Mo-doped Fe-Cr-Al alloy | ||||||||||||||

Sealing system |

|

|

| |||||||||||||

Vacuum degree: ≤10Pa (mechanical pump) | ||||||||||||||||

Pressure measurement and monitoring |

| The mechanical pressure gauge with damping oil is used to produce damping when the pressure fluctuates and reduce the pointer to swing back and forth. | ||||||||||||||

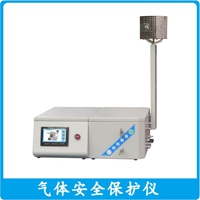

Gas supply system |

| Float flowmeter is used to control the flow rate of gas, integrated with the equipment, and the leakage test has been carried out before leaving the factory. | ||||||||||||||

Weakly corrosive gas preheater (Optional) |  | The whole body is made of 316L material, which can be preheated for various gases and corrosive gases to meet special process requirements, with a maximum temperature of 600 ℃. | ||||||||||||||

Net weight | 60KG | 60KG | 90KG | |||||||||||||

Cautions |

1. When the furnace temperature of the equipment is greater than or equal to 300℃, it is forbidden to open the furnace to avoid injury; | |||||||||||||||

Service | 1 year warranty with lifetime support (the warranty does not cover consumable parts, such as furnace tubes and sealing rings). | |||||||||||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Configuration

| 1. The material will roll radial and axial under the rotating pendulum vibration of the reaction chamber to ensure uniform heating of the material and adequate contact with the gas to prevent overburning and entraining caused by static sintering; 4. The product uses automatic control mode, equipped with 7-inch touch screen real-time tracking display device status; | |||||||||||||||

Model | NBD-RT1200-100TI | NBD-RT1200-100T2 | NBD-RT1200-100T3 | |||||||||||||

Electrical Spec | AC220V 4KW | AC220V 4KW | AC220V 6KW | |||||||||||||

Tmax | 1200 ℃ | |||||||||||||||

Max working temps. | 1100 ℃ | |||||||||||||||

Heating rate | ≤ 20 ℃/min | |||||||||||||||

Heating length | 440mm | 200mm*2(Single heating zone & 2-control) | 200mm*3(Single temperature and 3- control) | |||||||||||||

Tube size |

| |||||||||||||||

Temperature field distribution |

| As shown in the figure, this is the temperature zone curve of the equipment with single and double temperature zones | ||||||||||||||

Control system |

| 1. 15 temperature curves can be pre-stored to avoid the trouble caused by repeated setting of different experimental processes; | ||||||||||||||

Temp Accuracy | +/- 1 ℃ | |||||||||||||||

Heating element |

| Mo-doped Fe-Cr-Al alloy | ||||||||||||||

Sealing system |

|

|

| |||||||||||||

Vacuum degree: ≤10Pa (mechanical pump) | ||||||||||||||||

Pressure measurement and monitoring |

| The mechanical pressure gauge with damping oil is used to produce damping when the pressure fluctuates and reduce the pointer to swing back and forth. | ||||||||||||||

Gas supply system |

| Float flowmeter is used to control the flow rate of gas, integrated with the equipment, and the leakage test has been carried out before leaving the factory. | ||||||||||||||

Net weight | 60KG | 60KG | 90KG | |||||||||||||

Cautions |

1. When the furnace temperature of the equipment is greater than or equal to 300℃, it is forbidden to open the furnace to avoid injury; | |||||||||||||||

Service | 1 year warranty with lifetime support (the warranty does not cover consumable parts, such as furnace tubes and sealing rings). | |||||||||||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

|

推荐产品

High power PECVD system (Rotary Pendulum Vibration)

12L intelligent box furnace

NBD-LT cold and thermal fatigue testing machine

Intelligent tube furnace 1700℃

Anaerobic purification electrolytic furnace

Vertical silent mixing ball mill

Crucible for zirconia sintering

CVDO1200-XTIG3Z

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China