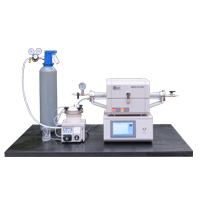

PECVD plasma chemical vapor deposition system

Release time: 2017-11-15 14:29:24 Number of views: 8476

Equipment introduction:

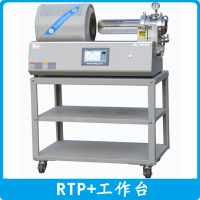

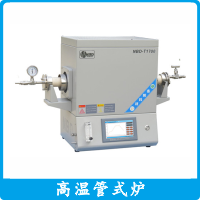

The product is composed of solid state plasma source, gas proton flow control system, substrate temperature control system, vacuum system, using centralized bus control technology of Nobardi operating software. It is suitable for SiO2 and SiNx film deposition at room temperature to 1200℃, and can realize TEOS source deposition, SiC film deposition and liquid gas source deposition of other materials. It is especially suitable for high efficiency protective film on organic materials and non-damaging passivation film deposition at specific temperature.

Configuration

| 1. Cleaning and coating in one go, eliminate secondary pollution; | |||||||||

Model | NBD-PECVD1200-80TI | |||||||||

Electrical Spec | AC220V 4KW | |||||||||

Tmax | 1150℃ | |||||||||

Heating rate | ≤ 20℃/min | |||||||||

RF power | 300 or 500W 13.56MHz | |||||||||

Tube size | Φ80*1200mm | |||||||||

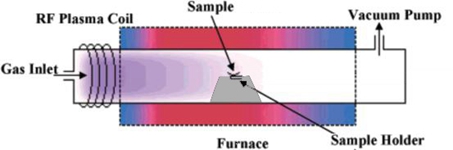

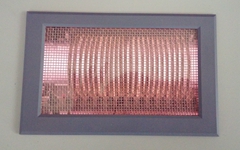

| Deposition diagram |

| This is a diagram of the deposition process of the device | ||||||||

Control system |

| 1.NBD-101EP embedded operating system Chinese and English interchange graphical interface, 7 inch real color touch screen input, intelligent man-machine dialogue mode, real-time heating power display, non-linear pattern temperature correction; The experimental report is generated independently, and the experimental data is exported for unlimited times. | ||||||||

Temp Accuracy | +/- 1 ℃ | |||||||||

Heating element |

| Mo-doped Fe-Cr-Al alloy | ||||||||

Sealing system |

|

|

| |||||||

Vacuum degree: ≤10Pa (mechanical pump) | ||||||||||

Pressure measurement and monitoring |

| The use of digital display vacuum gauge can make the vacuum degree of equipment more intuitive and the experimental results more accurate. | ||||||||

Gas supply system |

| Using two mass flowmeters to accurately control the gas flow rate, integrated with the equipment; | ||||||||

Net weight | 360KG | |||||||||

Cautions | 1. When the furnace temperature of the equipment is greater than or equal to 300℃, it is forbidden to open the furnace to avoid injury; the equipment caused by excessive pressure; valve must be installed on the cylinder. It is recommended to choose a small pressure reducing valve for test, and the measuring range of the valve is 0.01MPa-0.15MPa, which will be more accurate and safe in use. in the furnace tube and atmospheric pressure, maintain in the state of atmospheric pressure; furnace tube. If it is necessary to close the air valve to heat the sample, it is necessary to always pay attention to the indicator of the pressure gauge. If the absolute pressure gauge reading is greater than 0.15MPa, the exhaust valve must be opened immediately to prevent accidents (such as furnace pipe rupture, flanges flying out, etc.). | |||||||||

Service | 1 year warranty with lifetime support (the warranty does not cover consumable parts, such as furnace tubes and sealing rings). | |||||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Configuration

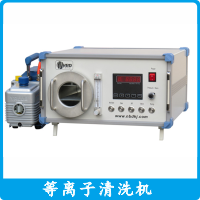

| 1. Cleaning and coating in one go, eliminate secondary pollution; | |||||||||

Model | NBD-PECVD1200-80TI | |||||||||

Electrical Spec | AC220V 4KW | |||||||||

Tmax | 1150℃ | |||||||||

Heating rate | ≤ 20℃/min | |||||||||

RF power | 300 or 500W 13.56MHz | |||||||||

Tube size | Φ80*1200mm | |||||||||

| Deposition diagram |

| This is a diagram of the deposition process of the device | ||||||||

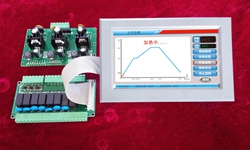

Control system |

| 1.NBD-101EP embedded operating system Chinese and English interchange graphical interface, 7 inch real color touch screen input, intelligent man-machine dialogue mode, real-time heating power display, non-linear pattern temperature correction; The experimental report is generated independently, and the experimental data is exported for unlimited times. | ||||||||

Temp Accuracy | +/- 1 ℃ | |||||||||

Heating element |

| Mo-doped Fe-Cr-Al alloy | ||||||||

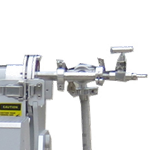

Sealing system |

|

|

| |||||||

Vacuum degree: ≤10Pa (mechanical pump) | ||||||||||

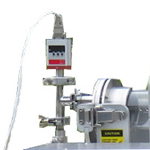

Pressure measurement and monitoring |

| The use of digital display vacuum gauge can make the vacuum degree of equipment more intuitive and the experimental results more accurate. | ||||||||

Gas supply system |

| Using two mass flowmeters to accurately control the gas flow rate, integrated with the equipment; | ||||||||

Net weight | 360KG | |||||||||

Cautions | 1. When the furnace temperature of the equipment is greater than or equal to 300℃, it is forbidden to open the furnace to avoid injury; | |||||||||

Service | 1 year warranty with lifetime support (the warranty does not cover consumable parts, such as furnace tubes and sealing rings). | |||||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

推荐产品

CVDO1200-XTIG3Z

Rf independent system

Constant voltage control system

Ultrasonic atomizing CVD tube furnace

Well type molten salt electroplating furnace

1500 ℃ (80L) ultra large capacity box furnace

medium frequency induction melting furnace

Ion sputtering coating instrument

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China