High temperature tube furnace 1500℃

Release time: 2017-09-28 17:57:40 Number of views: 5732

Equipment introduction:

High temperature tubular furnace not only has excellent shape and technology, but also can safely touch the shell when running at high temperature. The most valuable thing is that the position of the temperature measuring point is adjusted repeatedly by our technical personnel for a long time, so that the temperature of the temperature measuring point is very close to the actual temperature in the tube. At the same time, its temperature control is very accurate. Tubular furnace in high temperature field uses acid and alkali resistant, high temperature resistant, long service life corundum tube as the carrier of heating and sealing, so that the equipment is more stable.

Configuration

|

|

1. The furnace tube made of high purity alumina has excellent corrosion resistance and high temperature resistance. |

||||||||||

|

Model |

NBD-T1500-50TI |

NBD-T1500-60TI |

NBD-T1500-80TI |

||||||||

|

Electrical Spec |

AC220V 3KW |

||||||||||

|

Tmax |

1500 ℃ |

||||||||||

|

Max working temps. |

1450 ℃ |

||||||||||

|

Heating rate |

≤ 20 ℃/min |

||||||||||

|

Heating length |

310mm |

||||||||||

|

Tube size |

Φ50*1000mm |

Φ60*1000mm |

Φ80*1000mm |

||||||||

|

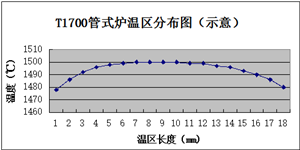

Temperature field distribution |

|

As shown in the figure: This is the temperature zone diagram of the equipment |

|||||||||

|

Control system |

|

1.NBD-101E embedded operating system Chinese and English interchangeable graphical interface, 7 inch true color touch screen input, intelligent man-machine dialogue mode, real-time heating power display, non-linear pattern temperature correction; |

|||||||||

|

Temp Accuracy |

+/- 1 ℃ |

||||||||||

|

Heating element |

Adopt high purity silicon carbon rod with good corrosion resistance

|

||||||||||

|

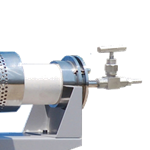

Sealing system |

|

|

|

||||||||

|

Vacuum degree: ≤10Pa (mechanical pump) |

|||||||||||

|

Pressure measurement & monitoring |

|

The mechanical pressure gauge with damping oil is used to produce damping when the pressure fluctuates and reduce the pointer to swing back and forth. |

|||||||||

|

Gas supply system |

|

Float flowmeter is used to control the flow rate of gas, integrated with the equipment, and the leakage test has been carried out before leaving the factory. |

|||||||||

|

Net weight |

30KG |

45KG |

|||||||||

|

Cautions |

1. When the equipment is in use, the reading of the absolute pressure gauge should not be greater than 0.15MPa to prevent equipment damage caused by excessive pressure. |

||||||||||

|

Service |

1 year warranty with lifetime support (the warranty does not cover consumable parts, such as furnace tubes and sealing rings). |

||||||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

|

|

|||

|

|

|||

|

|

|

|

|

推荐产品

Heat resistant material test furnace

Expansion coefficient tester

Float + vacuum system mobile platform

High magnetic induction quenching furnace

Small CVD system

Rotary microwave heating furnace

Intelligent double temperature zone tube furnace 1500℃

Vacuum molten salt electroplating furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China