Openable vertical tube furnace 1200℃

Release time: 2017-09-28 16:51:18 Number of views: 5148

Equipment Introduction:

The vertical tube furnace adopts a structural design of vertical placement of furnace tubes and annular distribution of furnace heating wires, which can be applied to quenching, annealing, tempering heat treatment of small steel parts, as well as vertical CVD coating. The equipment can operate in atmospheric and vacuum conditions, and can also be used as a regular tube furnace, suitable for universities, laboratories, research institutes, and other units.

| Equipment Introduction:

| |||

|

|

| ||

Configuration details

| Equipment features: | ||||||||||||||

Product model | NBD-LTO1200-60TI-150 | ||||||||||||||

Electrical specifications | AC220V 2KW | ||||||||||||||

Electrical specifications | 1200℃(<1小时) | ||||||||||||||

Long term use temperature range | 300~1150℃ | ||||||||||||||

Size of constant temperature zone | 100mm | ||||||||||||||

heating rate | 1℃/H-20℃/Min | ||||||||||||||

Heating zone length | 200mm | ||||||||||||||

Furnace tube size | Φ60*700mm | ||||||||||||||

External dimensions | 长760*高1400*深520mm | ||||||||||||||

control system |

| 1. Sintering process curve setting: dynamically display the setting curve, the equipment sintering can pre store multiple process curves, and each process curve can be freely set; | |||||||||||||

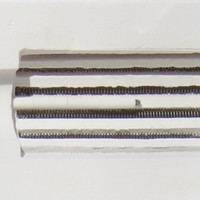

Heating element |  | Mo doped Fe Cr Al alloy | |||||||||||||

Temperature accuracy | +/- 1 ℃ | ||||||||||||||

Sealing system |

|

|

| ||||||||||||

Vacuum degree: ≤ 10Pa (mechanical pump) | |||||||||||||||

Pressure measurement and monitoring |

| Using a mechanical pressure gauge, the outer shell of the gauge is an airtight structure, which can effectively protect the internal components from environmental impact and debris intrusion, and has strong corrosion and high temperature resistance. | |||||||||||||

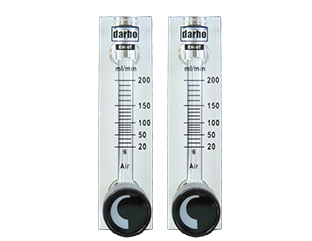

Gas supply system |

| The gas flow rate is controlled by a float flowmeter, which is integrated with the equipment and has undergone leak testing before leaving the factory. | |||||||||||||

Equipment usage precautions | 1. When the furnace temperature of the equipment is ≥ 300 ℃, it is prohibited to open the furnace to avoid injury; | ||||||||||||||

Service support | 1-year warranty with lifetime support (warranty does not include consumable parts such as furnace tubes and sealing rings) | ||||||||||||||

Disclaimer: The product introduction content on this website (including product images, product descriptions, technical parameters, etc.) is for reference only. Due to untimely updates, there may be some discrepancies between the described content and the actual situation. Please contact our customer service personnel for confirmation. The information provided on this website does not constitute any offer or commitment, and Novartis may periodically improve and modify any information on the website without prior notice.

推荐产品

High temperature, high pressure automatic feeding tube furnace

High Flux Intelligent Chamber Furnace

Double temperature rapid annealing slide furnace

Dual-channel K-type digital thermometer

Pilot scale molten salt electroplating furnace

Hydrogen reduction furnace with smooth bore

Anticorrosive mini muffle furnace

Large denture waxing furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China