Hydrogen reduction furnace with smooth bore

Release time: 2023-04-04 13:22:24 Number of views: 1176

Equipment introduction:

NOBODY intelligent smooth bore hydrogen reduction furnace is a special equipment developed for sintering, melting and analysis of metal, non-metal and other compound materials in atmosphere and vacuum in colleges and universities, scientific research institutes and industrial and mining enterprises.

The equipment is mainly composed of sliding furnace, stainless steel quick opening reaction chamber, liquid gas supply system, high vacuum molecular pump unit and gas safety protection system. The control system adopts advanced PLC and touch screen control system, and multi-protection function design, to ensure the safety of operators and equipment to the maximum extent. The system functions are highly integrated, which can easily and intuitively carry out experiment operation through the touch screen human-computer interaction system.

Five automatic sintering modes, dry hydrogen sintering, wet hydrogen sintering, low vacuum sintering, high vacuum sintering and protective atmosphere sintering, are preset in the system, and can be selected according to the process requirements. The whole experiment process is fully automatic control, sintering end, automatic removal of the furnace

(to achieve rapid material cooling), and automatically disconnect the gas at the set temperature, complete the whole experimental process.

Configuration

| Equipment characteristics 1, preset five automatic sintering modes, can also customize the sintering mode according to the needs of the experiment; 2, the system is stable and reliable, easy to operate, and the safety protection measures are perfect; 3, Adopt advanced PID self-learning fuzzy control, high temperature control accuracy, keep at ±1℃ (tube temperature control at ±2℃, constant temperature section); 4, the whole experiment process is fully automatic control, sintering end, automatic removal of the furnace (in order to achieve rapid material cooling); 5. With the function of Internet of Things, the device can be monitored and operated remotely through mobile phones and computers; 6, data storage function, can save the important parameters of sintering, as long as 30 days (boot 8 hours a day); 7, formula function, can pre-store more than 100 formula; 8, multiple anti-stay function, so that customers use more secure; 9, networking function, through the RJ45 interface, using TCP/IP protocol, the system can be connected to the upper computer (the upper computer needs to install the corresponding software). | ||||||

PRODUCT MODEL | NBD-CMT1200-158TI (G)2FYW-250W | ||||||

Tmax | 1150℃ | ||||||

power supply | 三相380V 50HZ | ||||||

rated power | 10KW | ||||||

Igniter ignition power | 0.6KW | ||||||

Igniter ignition method | Silicon carbon rod ignition | ||||||

Rated power of tropical belt | 115W | ||||||

Rated power of evaporator | 800W | ||||||

Sintering temperature constant temperature power | 2KW | ||||||

heating element | High quality iron chromium aluminum alloy wire | ||||||

Type of temperature measuring element | K-type thermocouple 420mm | ||||||

Heating temperature zone size | φ250*300mm | ||||||

Recommended heating rate | 3~5℃/min | ||||||

Rated flow rate of nitrogen | 8L/min | ||||||

Rated flow rate of hydrogen | 8L/min | ||||||

Flow range of peristaltic pump | ~12ML/min | ||||||

Furnace tube material | 310s | ||||||

Furnace tube volume | 10.5L | ||||||

Crucible material | 310s | ||||||

Crucible size | φ100mm*100mm | ||||||

Flow meter type | 0.5~8L/min float flowmeter (2 pieces) | ||||||

Protection function | Anti backfire, anti reverse suction, and anti overpressure | ||||||

Number and specifications of air intakes | Double card sleeve joint with a diameter of 6.35 (2 pieces) | ||||||

Vacuum pumping method | Vacuum pump 4L/s+molecular pump F-100/150 | ||||||

| Furnace body size | 长1550×深770×高1250mm | ||||||

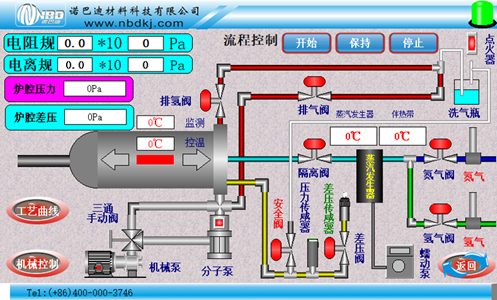

control system |

| 1. 15 temperature curves can be pre stored to avoid the trouble caused by repeated settings of different experimental processes; | |||||

Temperature Accuracy | ±1℃(管内控温在±2℃,恒温段) | ||||||

Process control interface |  | ||||||

Mechanical control interface |  | ||||||

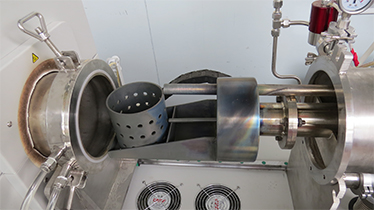

Stainless steel quick opening reaction chamber |

| ||||||

weight | 约370KG | ||||||

Service Support | 1-year warranty with lifetime support (warranty does not include consumable parts such as furnace tubes and O-rings) | ||||||

推荐产品

Blast drying oven (galvanized)

Vacuum well furnace

Vertical double tube sintering furnace

Crucible for zirconia sintering

well type furnace G1200-15TI

High temperature tube furnace 1500℃

Anti-corrosion mini chamber furnace

Sliding rail mobile fast annealing furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China